How To Recognize Combustible Dust Hazards

Combustible dust poses a significant risk to workers and facilities in various industrial settings. Preventing and protecting against these hazards can be quite challenging. When dealing with combustible dust, it’s crucial to conduct accurate laboratory testing to determine its combustibility or explosibility. Testing aids in identifying hazards associated with combustible dust, while a thorough Dust Hazard Analysis (DHA) helps identify and mitigate the risks associated with combustible dust.

In this technical blog post, we’ll focus on various aspects related to identifying and addressing combustible dust hazards and explosions, applying NFPA guidance, determining dust explosivity, and different approaches to conducting a Dust Hazard Analysis to help prevent incidents and protect the safety of your workplace and employees.

The following informational sections can be found in this article:

You can also read our accompanying blog post, “How To Prevent and Mitigate Combustible Dust Hazards,” to gain deeper insight into the proactive measures companies can take to manage these risks effectively.

What is combustible dust and its associated hazards?

Combustible dust refers to fine particles that can ignite and explode when suspended in the air in certain concentrations. These dust particles are generated from numerous materials such as metals, wood, plastics, and chemicals.

Understanding the properties and risks associated with combustible dust is crucial for maintaining a safe working environment. Varied industries, including agriculture, manufacturing, and food processing, are susceptible to combustible dust hazards. Common materials such as flour, sugar, coal, and metal powders can generate combustible dust. The accumulation of dust in confined spaces or on surfaces can create an explosive atmosphere, leading to catastrophic consequences.

The primary hazards of combustible dust include fire and explosions. An electrical spark or other ignition sources can trigger a dust explosion, resulting in property damage, injuries, and even fatalities. Additionally, inhaling dust particles can pose health risks, causing respiratory issues and other adverse effects.

What are the 5 elements of a combustible dust explosion?

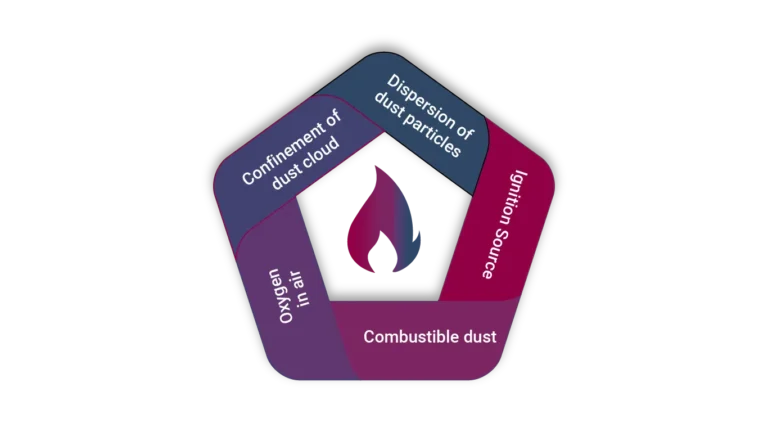

For a combustible dust explosion to occur, several critical factors must align. While the Dust Explosion Pentagon shares similarities with the conventional fire triangle—comprising of fuel, oxidant, and an ignition source—combustible dust hazards extend beyond these elements to include confinement and dispersion.

When all five elements of the Dust Explosion Pentagon are present simultaneously, there is a high risk of a combustible dust explosion occurring. Understanding and managing these elements are crucial for preventing and mitigating the hazards associated with combustible dust in the workplace.

Fuel: Combustible dust serves as the fuel for explosions. It can be in the form of solid particles from various materials, such as wood, metal, or agricultural products. Unlike conventional fires, where the fuel is typically in liquid or gas form, combustible dust particles must first be dispersed in the air to create an explosive atmosphere.

Oxidant: An oxidant, usually oxygen in the air, is necessary to support combustion. When combustible dust particles are suspended in the air, they mix with oxygen, creating the potential for rapid combustion and explosion.

Ignition Source: An ignition source is required to initiate the combustion reaction. This can be anything that provides sufficient energy to ignite the combustible dust particles, such as sparks, flames, hot surfaces, or electrical arcs.

Confinement: Confinement refers to containing or restricting combustible dust within a defined space. In confined spaces, such as equipment enclosures or ductwork, the accumulation of combustible dust and heat can create a volatile environment. Without proper ventilation or containment measures, the accumulated energy can reach a critical point, resulting in a catastrophic explosion.

Dispersion: Dispersion plays a crucial role in the severity of combustible dust explosions. When dust particles are dispersed in the air, the surface area available for combustion increases significantly. This leads to more rapid and violent combustion reactions than when dust particles are confined or compacted.

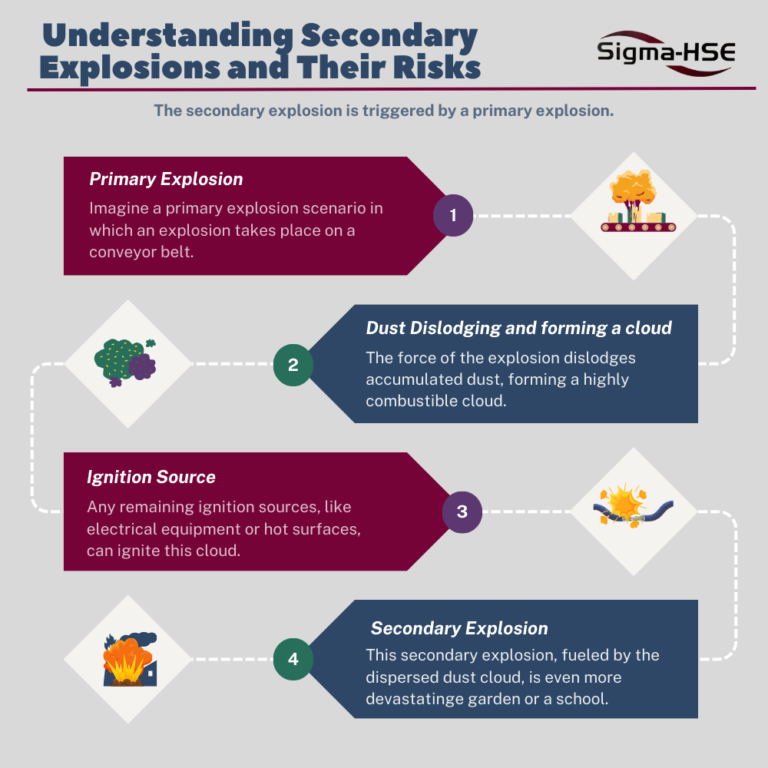

What are secondary explosions and their risks?

Secondary explosions occur when an initial dust explosion creates a shockwave that disturbs settled dust, leading to subsequent explosions. While the initial explosion may cause damage, it is often the secondary explosion that is most devastating.

For instance, imagine a scenario where an explosion occurs on a conveyor belt. Initially, the explosion may only damage the conveyor belt itself. However, the force of the explosion and the pressure wave it generates can dislodge accumulated dust from surrounding surfaces. This dust, now suspended in the air, becomes highly combustible.

In a confined space where dust has accumulated, the blast wave from the initial explosion can disturb this dust, forming a dust cloud. When ignited by any remaining ignition sources, such as electrical equipment or hot surfaces, this dust cloud can lead to a secondary explosion. Fueled by the dispersed dust cloud, the increased surface area of the dispersed dust allows for rapid combustion, resulting in a more extensive and devastating explosion.

To mitigate the risks of secondary explosions, it is essential to implement comprehensive combustible dust management practices, including proper housekeeping, equipment design for dust control, hazardous area classification, training for personnel, and the use of explosion protection measures such as deflagration vents, suppression systems, and isolation devices. Conducting a thorough Dust Hazard Analysis (DHA) can minimize the impact of both primary and secondary dust explosions in industrial facilities.

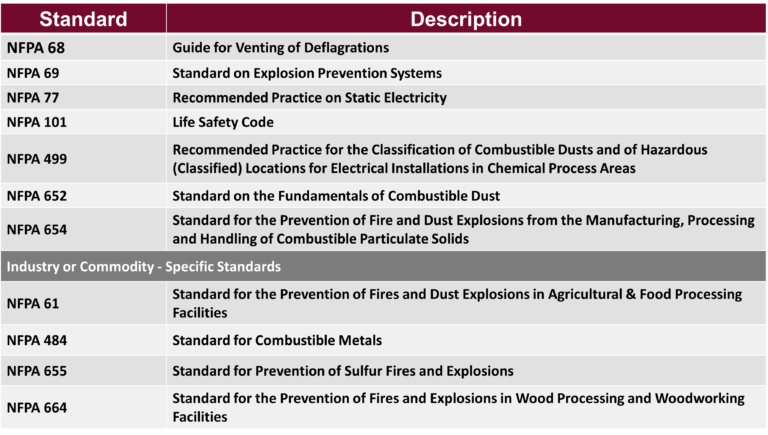

NFPA Standards for Combustible Dust Hazards

Numerous NFPA (National Fire Protection Association) standards are integral to managing and mitigating combustible dust hazards across industries. These standards provide comprehensive guidelines and best practices for preventing fires, explosions, and other safety risks associated with combustible dust. From venting deflagrations to classifying dusts and specifying prevention systems, NFPA standards cover a wide range of aspects related to combustible dust safety. Below is a list of key NFPA standards relevant to combustible dust hazards and their respective descriptions:

Explosibility of Dusts

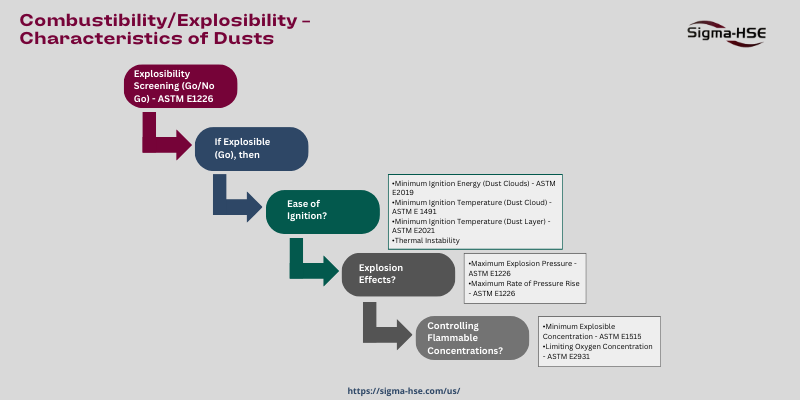

Determining Combustibility or Explosibility with Go/No Go Testing

Many individuals often inquire about the need for a dust hazard assessment to determine if their dust is explosive. The answer is unequivocally yes. The reason lies in the potential explosibility of materials used in various processes. Without accurate testing, it’s impossible to ascertain whether a material is explosible.

To conduct a dust hazard assessment, samples of the material must be tested in accredited laboratories capable of determining their explosibility. Relying solely on historical data or the absence of previous incidents is insufficient, as conditions may have changed over time or may differ from those in historical records.

Several factors influence the explosibility of materials, including particle size, humidity, and initial temperature. Particle size plays a crucial role, as finer particles have a greater propensity to suspend in the air, increasing the risk of dust explosions. Additionally, environmental conditions such as humidity and temperature can affect the combustibility of materials. NFPA recommends performing tests on materials rather than relying solely on literature data. Literature data may not accurately reflect the conditions under which materials are used or stored, making testing essential for ensuring safety.

Explosibility Screening (Go/No Go) – ASTM E1226

The Go/No Go explosibility screening is a critical step in determining whether a material has the potential to explode. This screening process is vital for assessing the explosibility of materials, especially those with high explosive potential.

This test determines whether a cloud of dust dispersed in the air is capable of propagating deflagration, which could lead to a flash fire or explosion. It is a purely qualitative test that categorizes a dust or powder into one of two groups:

Explosible – Flammable or explosive

Non-Explosible – Non-flammable or explosive

At the Sigma-HSE Laboratory, we employ specific testing methods to assess explosibility effectively. Testing is conducted using a 20-liter spherical vessel, providing an ideal environment for assessing the potential for deflagration. In cases where sample quantity is limited, a 1-liter cylindrical vessel (Hartmann Bomb) may be used to conduct the necessary screening tests.

It’s essential to recognize that not all materials will exhibit explosibility in dust form. Some materials, such as plastic dust and certain oxides like titanium dioxide or aluminum oxide, may not form explosible dust clouds but can still pose combustion hazards.

For example, while some plastic dust may not explode when suspended in the air, it can melt under certain conditions. Similarly, oxide materials may not form dust clouds but can still ignite and burn when exposed to heat.

Further Testing of Combustible/Explosible Dusts

Even if a material is tested non-explosible through a Go/No Go explosibility screening test, it’s crucial to continue with combustibility testing. Combustibility screening tests assess the material’s propensity to burn, providing valuable insights into its fire hazards and safety considerations.

If the material is indeed explosible, it’s imperative to conduct further testing to determine the ease of ignition. This involves identifying the minimum energy and temperature required to ignite the material.

This knowledge is essential in determining necessary safety measures, such as equipment bonding or grounding, or adjusting operational temperatures to mitigate risks posed by potential ignition sources prevalent in industrial settings. Determining the explosibility and ease of ignition of a material involves several crucial parameters:

Ease of Ignition:

- Minimum Ignition Energy (MIE) – ASTM E2019 (Test video)

- Minimum Ignition Temperature, Cloud (MITcloud) – ASTM E1491 (Test Video)

- Minimum Ignition Temperature, Layer (MITlayer) – ASTM E2021 (Test Video)

- Self-Heating/Thermal Instability – UN Test N.4, Class 4.

Once the ease of ignition is understood, attention must also be given to the potential effects of an explosion. Understanding the severity and consequences of an explosion is vital. This includes determining the maximum energy release, pressure exertion, burning velocity, and rate of reaction of the material. Such insights are crucial for deciding whether protective or preventive measures against explosion events are warranted for equipment and facilities.

Key parameters to consider include the following explosion severity effects:

- Maximum Explosion Pressure (Pmax) – ASTM E1226

- Maximum Rate of Pressure Rise (dP/dtmax) – ASTM E1226

- Dust Constant Value (KSt) – ASTM E1226

Identifying the minimum amount of material required for ignition and managing oxygen levels are fundamental safety considerations. Understanding the minimum explosible concentration and controlling oxygen levels can enhance safety by ensuring that combustion processes are adequately supported or suppressed.

For instance, reducing oxygen levels below the threshold required for combustion can effectively mitigate risks associated with flammable atmospheres. Additionally, controlling flammable concentrations plays a vital role in safety protocols. This involves:

Controlling Flammable Concentrations:

Dust Hazard Analysis: Identifying and Mitigating Dust Hazards

A Dust Hazard Analysis (DHA) is a comprehensive assessment to systematically evaluate potential fire, deflagration, and explosion hazards associated with dust in a process or facility. The primary objective is to recommend measures for effectively managing these hazards and ensuring a safe operating environment.

The analysis identifies safe operating ranges and assesses existing safeguards to mitigate fire, deflagration, and explosion events. Additionally, the DHA recommends further safeguards as necessary, accompanied by a detailed plan for their implementation.

Whether for existing processes and facilities or new constructions, a DHA is indispensable, with regulatory mandates often requiring completion as part of project protocols. DHAs must be periodically reviewed and updated at least every five years to uphold safety standards. Imperatively, the DHA must be conducted by individuals with proven expertise in the hazards associated with handling and processing combustible particulate solids to ensure a thorough and accurate assessment of potential risks and necessary safeguards.

Dust Hazard Analysis: Approaches and Importance

Dust Hazard Analysis (DHA) encompasses various approaches tailored to effectively evaluate and manage the risks associated with combustible dust. These approaches include:

Preliminary (Design-stage) Dust Hazard Analysis: This initial step involves a structured examination to identify potential dust hazards before conducting a more detailed DHA. It serves to lay the groundwork for comprehensive risk assessment.

Prescriptive-Based Dust Hazard Analysis: This approach follows established safety standards and guidelines to evaluate and manage combustible dust risks. It provides a structured framework for hazard analysis and mitigation measures.

Risk-Based Dust Hazard Analysis: Prioritizing risks based on severity and likelihood, this method offers a more flexible approach than strictly adhering to prescribed safety standards. It first focuses on addressing the most critical hazards to manage overall risk effectively.

Performance-Based Dust Hazard Analysis: Emphasizing specific safety outcomes rather than pre-defined standards, this approach aims to achieve comprehensive risk management tailored to the unique characteristics of each facility or process.

Hybrid DHA: Combining elements of both prescriptive and performance-based approaches, this hybrid method offers a versatile approach to dust hazard analysis, incorporating the strengths of each approach to enhance overall risk management.

Dust Hazard Analysis Revalidation: Periodically reviewing and updating the initial DHA ensures that it remains relevant and accurately reflects current operations, processes, and safety standards, maintaining the effectiveness of risk mitigation measures over time.

Combustible Dust Hazards: Preventive Measures and Hazard Control Strategies

To effectively recognize combustible dust hazards, it’s essential to understand the signs and symptoms and be aware of preventive measures and hazard control strategies. These measures include various strategies to reduce the likelihood of combustible dust incidents occurring in industrial environments.

Implementing rigorous housekeeping practices, conducting regular equipment inspections, and employing explosion protection measures, such as explosion venting and suppression systems, are crucial preventive measures. Also, controlling ignition sources, such as sparks from friction or electrical equipment, plays a significant role in hazard control.

By prioritizing these preventive measures and hazard control strategies, companies can significantly reduce the likelihood of combustible dust incidents and create safer working environments for their personnel. Check out our accompanying blog post, “How To Prevent and Mitigate Combustible Dust Hazards,” for more insights on managing these risks effectively.

At Sigma-HSE, we specialize in providing expert consulting and testing services worldwide. Our team of seasoned technical consultants and engineers have extensive experience in assisting various industries in managing combustible dust risks.