Our Solutions: Consulting

HAZOP (Hazard and Operability) studies, a common method of completing Process Hazard Analysis (PHAs), are recognized as an essential tool to identify deviations, improve process safety and reduce risk. By systematically identifying and analyzing potential deviations, HAZOP studies provide valuable insights to manage identified hazards, efficiency, and compliance.

During a hazard and operability study, multidisciplinary HAZOP team members examine possible consequences of a process or system using guided brainstorming sessions. By applying a set of predefined guidewords (such as “More,” “Less,” and “None”) to operating parameters complex processes, possible deviations from the intended design are explored to identify potential risks and operational challenges.

As a risk assessment tool, HAZOP is often described as:

HAZOP is best suited for assessing hazards in facilities, equipment, and processes and is capable of assessing systems from multiple perspectives:

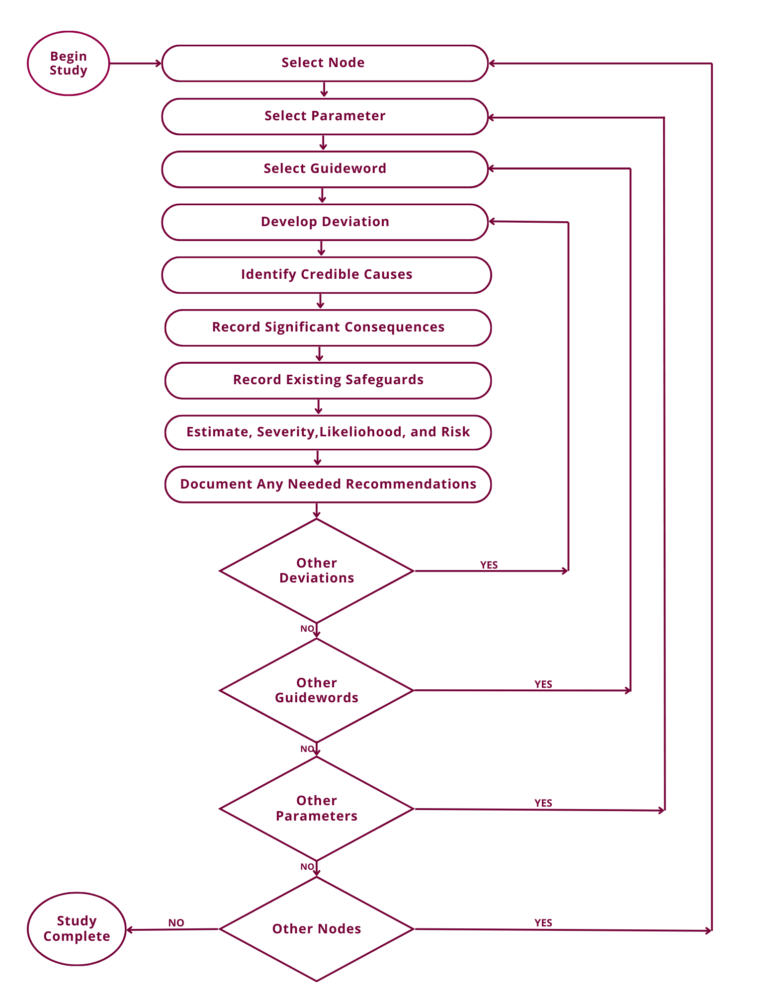

The stages of a HAZOP (Hazard and Operability Study) methodically build upon the information and analyses from the previous ones, ensuring a thorough and systematic risk assessment process that culminates in actionable safety enhancements.

The sequence unfolds in the steps below:

Key success factors in conducting HAZOP (Hazard and Operability Study) ensure several critical outcomes for the safety and efficiency of industrial processes:

Like a HAZOP, a HAZOP-LOPA identifies potential risks and makes recommendations but is a more detailed approach to identifying the likelihood of an event taking place. Using LOPA in combination with HAZOP the likelihood of a scenario taking place is determined with a combination of semi-quantitative, Probability of Failure on Demands (PFD). Industry accepted PFDs are taken to reduce the likelihood resulting in potentially fewer recommendations and decrease cost.

HAZOP systematically identifies and assesses potential hazards and operability issues in both batch and continuous processes. These evaluations pinpoint risks and operational challenges that can result from deviations in technological and organizational elements from the original design intent.

By systematically analyzing these potential hazards, HAZOP studies provide valuable insights to enhance safety, efficiency, and compliance. They also serve as the foundation for subsequent Layers of Protection Analysis (LOPA) and Functional Safety studies in the context of Process Hazard Analysis (PHA).

Watch our full on-demand webinar, “Importance of HAZOP Studies,” for an overview of HAZOP studies and guidance on implementing HAZOP across both national and international sites.

The HAZOP study is utilized to identify hazard and operational issues related to the materials, technology, and equipment in a process.

Using a range of process safety information by applying this methodology will identify potential hazards associated with dangerous materials and technological and organizational elements that may deviate from their original design intent.

HAZOP studies are conducted through many stages of a process. For new processes, a hazard and operability study is typically conducted during the early stages of process design.

It is recommended that the study takes place once the design and maintenance processes has been determined and fixed, and detailed piping and instrumentation diagrams (P&IDs) are available.

At this stage, specific process equipment items, such as pumps and their specifications, are known.

The HAZOP study allows industry experts to thoroughly understand the process control system, its potential deviations, and the safety measures implemented.

By conducting a HAZOP study early on (during the project development phase), timely responses to potential workplace hazards can be ensured, and necessary adjustments can be made to eliminate residual risks in later design stages.

This proactive approach helps businesses mitigate risks, while identifying potential hazards and creating a safer working environment.

For mature processes, HAZOP studies are typically revalidated every 5 years.

During a HAZOP study, a team of specialists from various scientific disciplines, led by a HAZOP facilitator, systematically examines relevant aspects of an operation.

The experts will include engineers, process safety specialists, operators, and maintenance personnel. In the study, specific scenarios are generated and prioritized based on their risk levels.

Safety, prevention, control, and mitigation measures are documented, and adequacy of existing processes and controls is assessed.

The recommendations and insights from the study are documented as part of a final deliverable.

Following the HAZOP study, additional analyses, such as risk assessments or layers of protection analyses (LOPAs), may be conducted to ensure the effectiveness and integrity of protection analysis of the measures in meeting recognized risk tolerability criteria.

Finally, an action plan is developed and the actions are implemented to achieve risk reduction.

With our onsite and online HAZOP services, we offer flexibility to meet diverse project requirements.

Our online HAZOP sessions provide the added advantage of bringing together teams of safety professionals from different sites and countries, enabling seamless collaboration and knowledge sharing on common process issues.

This eliminates the need for travel time and accommodation expenses, making it a cost-effective solution.

HAZOP studies are typically conducted by a multidisciplinary team of specialists with relevant expertise in engineering, process safety, operations, and maintenance.

The team is led by a HAZOP facilitator who guides the study and ensures its effectiveness.

Additional expertise is called upon as needed, such as subject matter experts from government agencies, original equipment manufacturers, and other individuals with in-depth knowledge of the specific process or system being analyzed.

The collective expertise of the various hazop analysis team members allows for a comprehensive examination of potential hazards.

Consultants play a crucial role in HAZOP studies due to their expertise, objectivity, and specialized skills.

They bring industry knowledge, experience, and a fresh perspective to the hazard analysis itself, ensuring objective hazard identification, risk assessment and risk management strategies to address potential hazards.

Their involvement helps streamline the hazard analysis process, saves time, and enhances the overall effectiveness of the hazop study process. Additionally, consultants can provide training and knowledge transfer.

Dedicated HAZOP team with specialist process knowledge

Wide range of industry experience across various sectors

Partnering with clients to ensure compliance in a cost-effective manner

Customized HAZOP training packages for improved hazard identification understanding

Trust Sigma-HSE to guide you through the HAZOP process, from design team facilitation to analysis and reporting.

Contact us today to learn more about how our HAZOP studies and safety procedures can benefit your organization and contribute to a safer and more efficient working environment. If you require process hazard analysis (PHA) solutions, you can learn more here.

Undertaking Hazard and Operability studies are an important aspect for organizations in keeping people, business and the environment safe. Learn more about how our HAZOP analysis solutions can support your organization with safety risks.

Are you visiting Sigma-HSE from outside your region? Visit your regional site for more relevant process safety solutions.