Combustible Dust Testing - Why Results Matter

In today’s world, accurate data is one of the most important jigsaw pieces for businesses across every industry. It can predict business trends and help prepare businesses for production changes. It can even notify you about how violent a potential combustible dust explosion is likely to be. Essentially, data tells us what we should do next. It reveals shortcomings and inefficiencies, and it illuminates what is feasible, and what may trigger dust explosion events. But data can only be utilised if it is rigorously acquired.

So why does the accuracy and structure of your combustible dust test data matter?

Firstly, it doesn’t make sense to design or make changes to your process safety protection systems without rigorously verified combustible dust test data. Unreliable dust data could directly harm your business, your people, your workplace and the wider environment via an unanticipated dust explosion or fire.

Secondly, unreliable testing data doesn’t add any value to the quality of your process designs. In order for your process design to be secure, you must have meaningful material data.

What is combustible dust?

The first step in understanding your data is to understand the material from which you are leveraging the data.

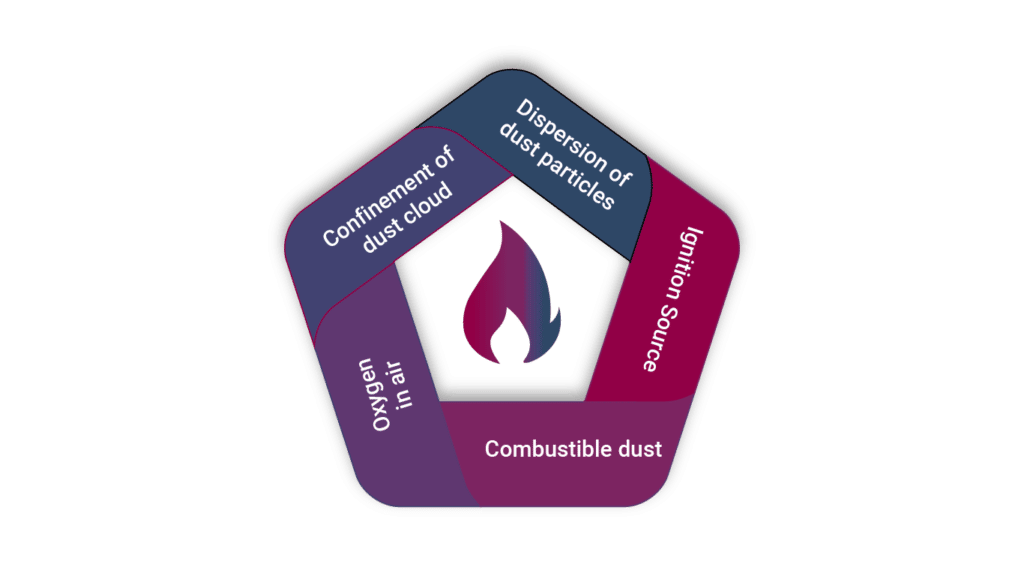

Combustible dust is any substance that has the potential to become dispersed and suspended in the air as a dust cloud. When exposed to an ignition source, an explosion may occur. Most solid organics (e.g. sugar, flour, grain, and wood), carbonaceous materials (charcoal, soot, coal), textile fibres (cotton), metals, and some non-metallic inorganic elements may produce combustible dust.

Even materials that may not “normally” be combustible can burn or explode if the dust particles are the right size and are at the right concentration.

The propensity of the hazard is primarily associated with the particle size distribution or fineness of the dust or powder. The shape and size of the dust particles, alongside a range of other factors, may affect the force of a dust explosion. Understanding the data behind particle size, shape and moisture concentration makes up a large part of an accurate dust data set.

*Powdered substances that are not fully oxidised will generally be capable of combustion. This will include many organic powders used within operations. Whether a specific powder is combustible cannot be calculated, testing should be undertaken.

Dust test data reliability and your process

Every business must be able to rely on reliable dust combustibility test data. Decisions that are made regarding explosion prevention and protection measures will be based on collected data, and inaccurate data can put lives at risk.

In addition, relying on inaccurate dust data can sometimes over-classify potential prevention and protection measures. This can lead to unnecessary financial expense in terms of purchasing and maintaining ATEX-certified and other hazardous area equipment (if relevant to your particular process).

Even from a business management standpoint, your dust combustibility data must be entirely accurate and reliable, as the effort and expense to build, design and/or maintain any aspect of your process can be undermined through ineffective data.

Your dust test data and the Dangerous Substances and Explosion Atmosphere Regulations (DSEAR)

It is a specific duty of an operator under DSEAR to ensure the hazards of fire and explosion are identified, and measures are implemented to control the risks of fires or dust explosions. These dust safety measures must be maintained to ensure their effectiveness.

Some operations have the capability of resulting in fire and dust explosions because they involve substances classified as flammable and oxidising under the Classification, Labelling and Packaging Regulations 2015; operate processes whereby non-classified substances are present at temperatures and pressures which render the substances as if they were classified as flammable, and involve substances (combustible powders and dust) which can form flammable/air mixtures in processing operations.

To comply with DSEAR regulatory requirements and health and safety policies, potential fire and dust explosion hazards and risks must be identified. This applies to existing processes and to any modification to processes, plants, or substances. The identified hazards should either be eliminated, or the risks reduced to an As Low level As is Reasonably practicable (ALARP) by modifying the existing, new or modified process, project, plant or applicable substance. reasonably practicable (ALARP) by modifying the existing, new or modified process, project, plant or applicable substance.

Where does reliable test data come from?

A variety of laboratory experiments have been created and improved to characterise explosion and ignition potential of combustible dust. Each test is intended to provide single-value data set for testing dust, powders and other materials that are used across a wide range of processes and processing equipment by simulating normal operations under “worst case” scenarios.

Although there is an abundance of test data that is available from reliable literature sources, data for dust and powders are less dependable than for other materials i.e. gases and vapours. Again, variables such as particle size or moisture content can significantly alter flammability properties, so rigorous testing is the best solution.

Furthermore, published literature or Material Safety Data Sheets (MSDS) for powders may only supply generic values for dust or powder materials, and in some cases, the data provided is outdated or may have been determined using dated testing techniques.

Understanding what test method to undertake

Dust Combustibility (Group A/B)

This specific standardised test determines whether particular dust or powder is combustible. If the test results in material ignition, then the substance is categorised as Class A. If no ignition occurs, the substance is Class B.

Particle Size Distribution

Generally, only fine, dusty powders are capable of combustion. A powder of fewer than 500 microns can form flammable atmospheres and be capable of combustion. Often, only a proportion of the powder will be less than 500 microns and the larger particle size fractions will temper the explosive characteristics.

In some processing operations, a bulk powder containing a small proportion of fines will not sustain combustion; but other processes will deliberately handle finer materials, i.e within dust extraction and collection systems; or the material may be friable resulting in the generation of fines. Most testing of combustible dusts will be undertaken on the less than 500-micron fraction.

Minimum Explosible Concentration (MEC)

The minimum concentration of fine powder within flammable dust clouds (in g/m3) that is capable of combustion. The MEC is extremely substance-specific and cannot be calculated.

Minimum Ignition Energy (MIE)

The minimum amount of energy necessary to ignite a dust flammable atmosphere. The value of MIE is, again, substance-specific and can range from <1 mJ to in excess of 1000 mJ. This value can only be determined by testing. MIE can be determined using two types of ignition sources – capacitance or induction. The capacitance test mimics ignition via an electrostatic energy source; whereas the inductance test mimics ignition via mechanical means. If the test results indicate the MIE is greater than 1000 mJ then it can be concluded that electrostatic discharges (other than propagating brush discharges) and mechanically generated sparks would not be an effective ignition source for flammable dust clouds.

Minimum Ignition Temperature (MIT)

The minimum temperature of hot surfaces that are capable of igniting a flammable dust cloud.

Layer Ignition Temperature (LIT)

The minimum temperature needed to ignite a 5mm layer of accumulated dust.

Both the MIT and LIT are required to be determined to allow for the specification of potential hot equipment items. A simple formula is therefore used to determine the maximum allowable temperature of any electrical or mechanical items of equipment that are present. The formula for the maximum allowable temperature is the lowest of either 2/3 of the MIT value or the LIT value minus 75K.

For example, if the MIT test result is 470°C and the LIT value is 350°C, then the maximum allowable temperature is 275°C.

Resistivity

This relates to the accumulation of electrostatic charge in a powder. Any powder movement (pneumatic conveying, etc) will generate an electrostatic charge. The resistivity of the powder will determine how easily that charge can be dissipated to earth. High resistivity powders act as insulators so any charge generated will tend to accumulate on the powder. An accumulated electrostatic charge may discharge in the processing operation, and if a flammable dust atmosphere is present, it will create an effective ignition source.

This is the maximum pressure that can be produced by the ignition of a flammable dust cloud. For powders, this can range in value up to around 12 bar. This parameter is used when designing containment systems.

This value is the maximum rate of pressure rise of the ignited dust explosion (dP/dt). This can be used during the design of relief and suppression systems.

This is simply the categorisation of the Kst value and is related to the efficacy or severity of a dust explosion. There are three classes of St class – 1, 2 or 3. St class 3 combustible dusts create the most severe dust explosions.

- St 1 – 1-200 bar.m/s

- St 2 – 201-300 bar.m/s

- St3 – >300 bar.m/s.

* Powdered substances that are not fully oxidised will generally be capable of combustion. This will include many organic powders used within operations. Whether or not a specific powder is combustible cannot be calculated, and must be tested.

Collecting and maintaining cohesive dust explosion testing data

One of the biggest mistakes companies can make is to dilute their test data by obtaining dust data with an alternative testing method, accreditation or calibration.

If a laboratory is accredited to ISO/IEC 17025 it gives that laboratory, the equipment and the results they produce credibility. ISO 17025 enables

“Laboratories to demonstrate that they operate competently and generate valid results, thereby promoting confidence in their work both nationally and around the world.

It also helps facilitate cooperation between laboratories and other bodies by generating wider acceptance of results between countries. Test reports and certificates can be accepted from one country to another without the need for further testing, which, in turn, improves international trade.”

Even if the laboratory isn’t accredited to ISO 17025, it might still have other quality systems i.e. GLP (Good Laboratory Practices) and/or ISO 9001. The truth, however, is that an organisation must be aware of data credibility and must maintain this credibility to ensure that robots process safety measures are put in place.

The lack of awareness regarding the dilution of dust data can be fatal for your business, people, workplace and the environment. If assumptions are being made regarding the quality of data being provided it creates room for error. For example, if a manufacturing business were to get consistent MIE results from an accredited laboratory and then unexpectedly receive results from an alternative unaccredited test house, would these results be used to help design or edit an explosion protection system? No.

The above is wildly hypothetical, but it does aid in understanding that you can’t trust your results if there’s no standardisation for data collection. Monitoring and continuously improving standardised data collection also increases team productivity as all requested data arrives in a homogeneous format that can easily be taught, shared and understood.

Using test data to work collaboratively

Combustible dust testing requires collaboration between departments, operational staff and, when necessary, between client and consultancy service. Only through a deep understanding of a process and how test data integrates into that particular operation, will test data be as effective as possible.

The fact that many teams are frequently unsure of data availability and what data is pertinent to solving operational problems is one of the main obstacles to utilising the true value of test data. Finding the data sources most suitable for achieving process safety goals, can be solved through collaboration.

Successful data collaboration requires an intentional approach driven by a mutual understanding of result trust (Standards of Accreditation) and operational confidentiality. A data collaboration framework built around these two pillars ensures that the client organisation maximises benefits while minimising risk.

By nature, data collaboration involves people from different departments and often, third parties working together. When specialist teams bring together specialist knowledge insights can be arrived at faster. This benefit is especially valuable for operations that have time-sensitive dates that they need to adhere to. Although speed and productivity matter when it comes to many industries, process safety by definition, tries to prevent major events, disasters, catastrophes, big fires, a consequential explosion hazard or toxic releases.

Conclusion

The process safety performance of your company and its operation is dependent on the proper integration and usage of reliable combustible dust test data. It is advantageous to have a detailed understanding of how your combustible dust test data will ensure that your prevention or protection procedures and equipment will operate under abnormal circumstances.

Planning ahead should enable you to develop a streamlined process for dust test data management, but this data must be reliable, cohesive and well-maintained to ensure their effectiveness.

Sigma-HSE are recognised global experts in the process safety industry. We are specialists in implementing risk assessments such as ATEX, DSEAR, DHA, and process risk evaluations across a variety of industries. If you’re unclear of the fire and explosive characteristics of your dust and powders, Sigma-HSE’s ISO 17025 combustible dust and powder testing and analysis laboratory can conduct all necessary tests and work with you to develop data from our dust testing services.