What is Process Hazard Analysis and its Comparative Study of Methodologies

Process Hazard Analysis (PHA) is an essential element in ensuring safety within industrial processing facilities and manufacturing plant operations. It provides a systematic approach to identifying, assessing, and managing risks associated with potential unwanted events such as explosions, fires, and toxic releases.

Various established techniques are employed in PHA to comprehensively analyze process hazards. These methodologies consist of primary and follow-up methods, each with its own benefits and drawbacks. This technical blog explores different aspects of Process Hazard Analysis and primary and follow-up methodologies used in PHA.

This article covers the following informational sections:

What is Process Hazard Analysis?

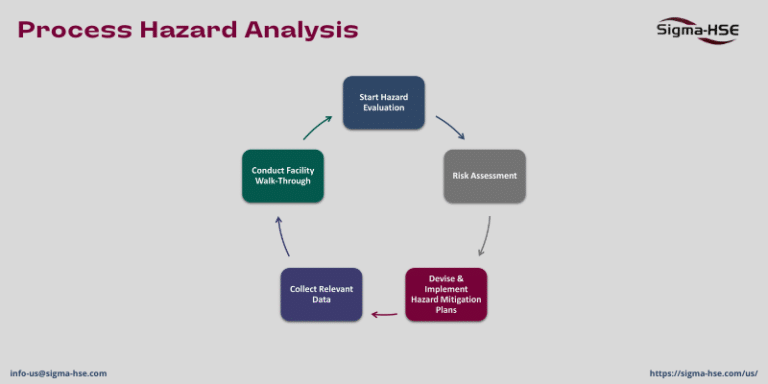

Process Hazard Analysis, focused on identifying potential causes, consequences, mitigation, and prevention of fires, explosions, releases of toxic or flammable chemicals, and major spills of hazardous chemicals, concentrates on assessing equipment, instrumentation, utilities, human actions, and external factors that could impact the process.

To illustrate, imagine a refinery in its conceptual or design phase, where a team conducts process hazard analysis by reviewing each operation to identify associated hazards, whether from materials, equipment, processes, or external factors. Through hazard identification, the team devises mitigating approaches to prevent such hazards. Various methodologies can be employed, starting with facility walkthroughs to assess operations, followed by hazard assessment to categorize risks and propose implementation and mitigation strategies. This analysis occurs during the initial conceptual phase or during operational modifications, aiming to identify hazards before they escalate into catastrophic events.

Process Hazard Methodologies

- Primary Methods:

- Hazard Identification Study (HAZID)

- PSM Checklist

- What-If? Analysis

- Hazard and Operability Study (HAZOP)

- Follow-up Methods:

- Layers of Protection Analysis (LOPA)

Hazard Identification Study (HAZID)

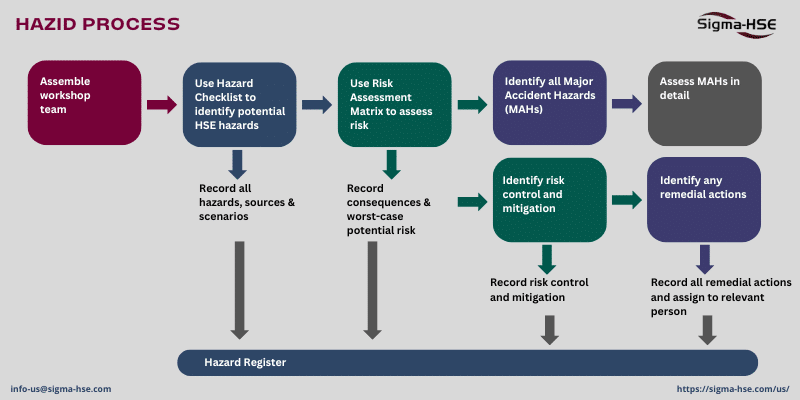

A Hazard Identification Study (HAZID) is a systematic and comprehensive process used in process safety consulting to identify and analyze potential hazards associated with a particular facility, process, or project. The primary goal of a HAZID is to identify and assess potential risks early in the design or operational phase so that appropriate measures can be taken to prevent or mitigate these risks. This involves identifying potential hazards during the conceptual design phase through collaborative brainstorming sessions, facilitating the comparison of risks associated with various options.

By addressing hazards at this early stage, teams can develop strategies to mitigate risks, thus minimizing the need for extensive safety modifications or equipment alterations once operations commence. This proactive approach is vital for ensuring safety and competitiveness within the industry. Recognizing and tackling hazards during the conceptual phase is essential for effective safety management and sustaining a competitive advantage in the market.

Advantages of HAZID

Early Risk Identification – Allows for the timely recognition of potential risks during the design phase, enabling adequate planning for hazard mitigation.

Multidisciplinary Approach – Involves a diverse team of professionals, such as chemical engineers, mechanical engineers, and safety engineers, offering varied perspectives for comprehensive hazard assessment.

Comprehensive Coverage – Provides a thorough examination of operations, equipment, and processes, resulting in a broad range of hazard identification.

Improved Decision-Making – Facilitates informed decision-making by addressing hazards early, aiding in determining the feasibility of operations and safety measures.

Cost Savings – Enables cost-saving opportunities by incorporating safety measures during the initial phases, reducing the need for extensive modifications later on.

Low Time Commitment – Requires relatively less time compared to other hazard assessment methods, making it efficient and feasible.

Can be Completed Prior to P&ID Development – Allows for hazard identification before detailed engineering, providing valuable insights for early-stage safety planning.

Disadvantages of HAZID

Subjectivity – Subject to varying opinions within the team, making reaching a consensus on specific risks or consequences challenging.

Limited Predictive Accuracy – Lacks quantitative data during the conceptual phase, limiting the accuracy of hazard predictions and assessments.

Focus on Design Phase – Primarily conducted during the design phase, limiting its applicability once operations are underway.

Resource Intensive – Requires significant resources, including expertise and time commitment from a diverse team, potentially increasing costs.

Limited to Identified Scenarios – Challenges in identifying all potential hazard scenarios during the conceptual phase, as some hazards may only become apparent during operational phases.

Easy to Miss Potential Hazards – If the team lacks adequate knowledge or experience in the specific operations, certain hazards may be overlooked, compromising the effectiveness of the assessment.

PSM Checklist Analysis

A Process Safety Management (PSM) Checklist analysis involves systematically using a checklist to assess and ensure the implementation of critical process safety elements within an organization. This checklist serves as a tool to evaluate whether the organization is effectively incorporating essential components of a robust safety management system. It consists of a prepopulated list of hazards and appropriate safeguards, aiming to guarantee that new implementations of known processes maintain the required level of protection. Checklists should be reviewed an updated on a regular basis.

Advantages of PSM Checklist Analysis

Systematic evaluation – Facilitates a structured assessment of process safety measures by adhering to standardized criteria.

Standardization – Ensures consistency in evaluating safety procedures across different operations.

Easy to follow – Simplifies the assessment process with clear guidelines and predetermined questions.

Documentation – Helps in documenting safety-related information and discrepancies for future reference.

Identification of deficiencies – Allows for easy identification of areas needing improvement or lacking safety measures.

Training tool – Can serve as a training resource to educate personnel on safety protocols and standards.

Low time commitment – Requires less time compared to more complex assessment methods.

Easy to use – Provides a straightforward approach for assessing and documenting safety measures.

Iterative process – Utilizes past experiences to refine safety measures and improve future assessments.

Disadvantages of PSM Checklist Analysis

Subjectivity – Assessments may be influenced by individual opinions within the team, leading to subjective interpretations.

Limited depth – The checklist may not delve deeply into complex safety issues, potentially overlooking nuanced concerns.

Overreliance – Organizations may become overly dependent on the checklist, neglecting broader safety considerations.

Inflexibility – The static nature of the checklist may hinder adaptability to unique organizational needs or emerging hazards.

Not comprehensive – Limited to the hazards and safeguards listed on the checklist, potentially missing new or emerging hazards.

Limited context – May not provide a full understanding of the broader safety context or operational complexities.

Doesn’t allow for identification of new hazards – Focuses solely on hazards mentioned on the checklist, excluding emerging risks.

Lacks cause-and-effect exploration – Doesn’t provide in-depth analysis of cause-and-effect relationships available in other methods.

What If? Analysis

A Process Safety Management (PSM) What-If analysis involves a structured discussion among a multidisciplinary team to explore hypothetical scenarios and evaluate their potential consequences. The objective is to proactively identify and understand potential risks, leading to the development of effective risk mitigation strategies. This approach involves asking “What if?” questions to stimulate brainstorming sessions aimed at uncovering potential hazard scenarios. For instance, questions may revolve around scenarios such as a reactor failure or the absence of fuel. By examining various hypothetical situations, teams can assess risks, explore likelihoods, severities, and existing safeguards.

Advantages of What If? Analysis

Early hazard identification – Hypothetical scenarios prompt brainstorming sessions that help identify potential hazards early in the process.

Multidisciplinary approach – Involves a team effort from diverse backgrounds, ensuring comprehensive risk assessment.

Flexible and adaptable – Allows for exploration of various hypothetical scenarios, enhancing flexibility in risk assessment.

Promotes team communication – Stimulates team discussions and collaboration, leading to more effective decision-making.

Qualitative insights – Provides qualitative assessments based on team discussions, offering valuable insights into potential risks.

Documentation – Facilitates documentation of brainstorming sessions and identified hazards for future reference.

Complement to quantitative methods – While not quantitative, What-If analysis serves as a valuable complement to quantitative risk assessment methods.

Easy to use – Provides a straightforward approach to exploring potential hazards and identifying risk mitigation strategies.

Requires less effort than HAZOP – Compared to more complex techniques like HAZOP, What-If analysis requires less time and effort.

Disadvantages of What If? Analysis

Subjectivity – Assessments may be influenced by individual opinions within the team, leading to subjective interpretations.

Lack of quantitative data – Relies on qualitative assessments, lacking quantitative data to support risk evaluations.

Resource intensive – Requires knowledgeable and skilled team members to conduct effective What-If analyses.

Limited to identified scenarios – Focuses solely on hypothetical scenarios raised during the analysis, potentially overlooking other risks.

May not capture rare events – Limited to exploring scenarios based on known hazards, may not consider rare or unexpected events.

Difficulty in ranking risks – Challenges may arise in prioritizing and ranking risks identified during What-If analyses.

Less comprehensive than HAZOP – What-If analysis may not provide the depth and comprehensiveness of HAZOP in identifying and mitigating risks.

Requires a knowledgeable and skilled team – Effective What-If analysis requires a team with expertise in process safety to maximize its benefits.

Hazard and Operability Study (HAZOP)

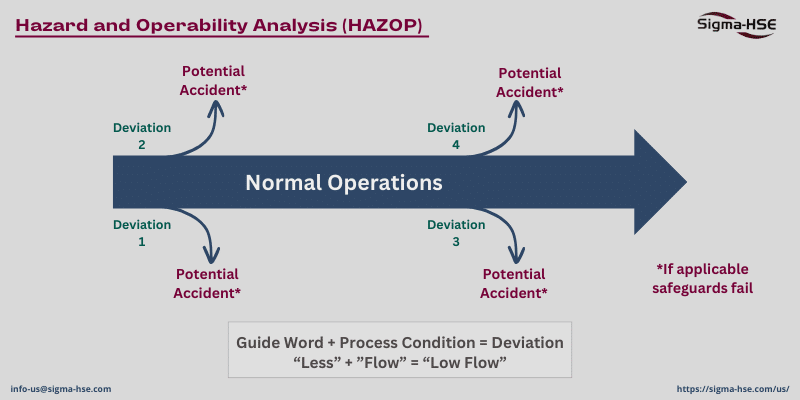

Hazard and Operability Studies (HAZOP) are systematic and structured hazard analysis techniques used in process safety to identify potential hazards and operability issues in a facility, system, or process. The primary objective of HAZOP is to examine each component and operation of a system to identify deviations from the intended design and assess their potential consequences.

During a HAZOP analysis, individual components, also known as nodes, are scrutinized along with their associated parameters, guidewords, and potential deviations. Unlike hypothetical questioning, HAZOP employs specific keywords to guide the analysis. For instance, when assessing a tank or silo, scenarios such as the tank being empty or the system overheating are considered. Each node or operational segment is then evaluated based on these predetermined guidewords.

A review of a process that includes nodes, parameters, guidewords, and deviations to identify credible causes of hazardous scenarios. Once a credible scenario is identified a risk ranking is performed identifying likelihood and severity of the scenario. Existing safeguards are evaluated, and a determination is made if additional safeguards are required.

HAZOP uses a standard list of Guidewords as modifiers to process Parameters to hypothesize Deviations from the desired intent.

Deviation = Guideword + Parameter

The team then evaluates these Deviations to determine if they could lead to hazardous conditions or significant operating upsets. Understanding the intended design is crucial for identifying meaningful deviations.

· No or NONE | = | The complete negation of the intent |

· MORE | = | A quantitative increase over desired intent |

· LESS | = | A quantitative decrease below desired intent |

· As Well As | = | A qualitative increase, such as an additional activity |

· PART OF | = | A qualitative decrease, such as an incomplete activity |

· REVERSE | = | The logical opposite of the intent |

· OTHER THAN | = | The complete substitution, i.e., no part of the intent occurs, but something else occurs |

Advantages of HAZOP

Comprehensive Analysis – HAZOP provides a detailed examination of each aspect of the process, considering various guidewords and deviations to assess hazards and associated risks thoroughly.

Early Identification of Risks – Risks can be identified as early as the conceptual and design phases, aiding in risk management from the outset.

Multidisciplinary Approach – HAZOP involves a team of experienced professionals, including chemical engineers, safety engineers, and mechanical engineers, ensuring diverse expertise and insights.

Structured Methodology – It follows a structured approach with specific guidelines, deviations, and keywords, systematically analyzing operations from node A to node B to node C.

Effective Communication – HAZOP encourages teamwork and facilitates effective communication among team members, leading to a comprehensive understanding of potential risks.

Documentation – The process is properly documented, providing a record of identified hazards and recommended actions for risk mitigation.

Review of Operational Concerns – In addition to safety concerns, HAZOP allows for the review of operational issues, providing a holistic assessment of the process.

Disadvantages of HAZOP

Resource Intensive – HAZOP requires significant time and resources, often taking more than a week to complete, as it involves a thorough review of each operation by a team of experts.

Subjectivity – The analysis may be influenced by the subjective opinions of team members, although an experienced team leader can guide the process effectively.

Focus on Known Deviations – HAZOP primarily focuses on identified deviations and may overlook dynamic system changes or emerging risks not covered by the predefined guidelines.

Limited Quantitative Analysis – The methodology lacks quantitative analysis, relying more on qualitative assessments of risks and deviations.

Requires Skilled Facilitator – Conducting a HAZOP study necessitates a skilled and experienced facilitator to lead the team effectively and ensure a thorough analysis.

Time-Consuming – The process is time-consuming due to its comprehensive nature and the need for detailed examination of each operation.

Complexity – HAZOP may generate a large number of recommendations, making it more complex and requiring a learning period for teams to grasp fully.

Layer of Protection Analysis (LOPA)

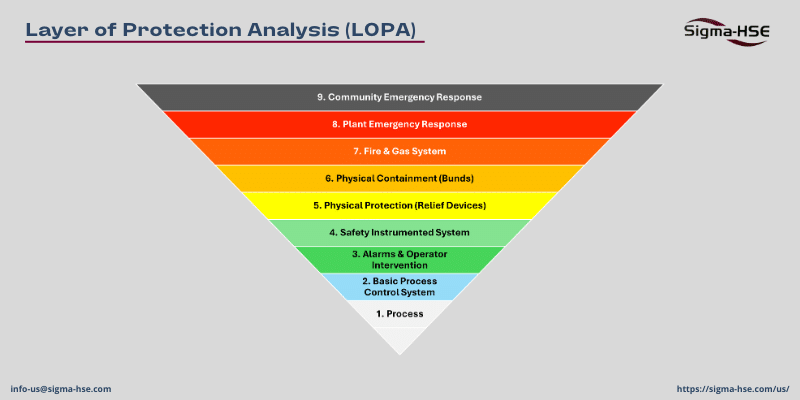

Following a Hazard and Operability Study (HAZOP), where rare undesired events are identified, a Layer of Protection Analysis (LOPA) is often conducted for specific systems with exceptionally high associated risks.

Layer of Protection Analysis (LOPA) is a risk management technique used in the process industry to assess and control risks associated with hazardous processes. The aim is to ensure that multiple independent layers of protection are in place to reduce the risk of a hazardous event to an acceptable level.

LOPA employs a structured approach to decision-making regarding safety investments, providing clarity in assessing risk levels and determining necessary risk reduction measures. For instance, if the HAZOP identifies a high risk of overheating, LOPA can quantify the risk level and propose measures to reduce the operating temperature based on quantitative data.

Advantages of LOPA

Simplified Risk Assessment – LOPA offers a straightforward method for assessing and managing risks associated with hazardous processes.

Focus on Critical Scenarios – It emphasizes critical scenarios identified during the HAZOP, allowing for targeted risk mitigation efforts.

Quantitative Analysis – LOPA utilizes quantitative data to assess risk levels, providing a more precise understanding of potential hazards.

Facilitates Decision Making – By providing structured risk assessment and mitigation strategies, LOPA aids in decision-making regarding safety investments.

Disadvantages of LOPA

Subjectivity in Parameters – LOPA may involve subjective parameters, which could impact the accuracy of risk assessments.

Limited Detail – It may lack comprehensive detail, especially in complex systems, potentially overlooking certain aspects of risk.

Assumption of Independence – LOPA assumes independence among protection layers, which may not always hold true in practice.

Limited for Complex Systems – LOPA may have limitations when applied to highly complex systems, where the interactions between various elements are intricate and difficult to assess.

Process Hazard Analysis remains a crucial tool for risk management in industrial processes. Through a comparative study of its methodologies, we’ve explored the intricate balance between the benefits and drawbacks inherent in each approach. As industries continue to evolve, the adoption of robust PHA practices promises to foster safer workplaces, ensuring not only compliance with regulatory standards but also the preservation of human lives and environmental integrity. You can watch our Webinar on Differing Methodologies of PHA.