Basis of Safety: A Comprehensive Approach

A comprehensive approach to risk is essential in process safety management. As industries become more complex and the potential risks grow, adopting a comprehensive approach to safety becomes non-negotiable. This post explores the Basis of Safety (BOSS) framework,

This first installment of our two-part series explores the Basis of Safety (BOSS) framework, designed to safeguard lives, protect the environment, and secure assets by integrating risk management into every facet of industrial operations. In this article, we will explore key concepts of BOSS, its relationship with Hazard and Operability Studies (HAZOP), the EHS hierarchy, and the core principles that guide effective safety management.

Here’s what you can expect to learn in this article:

Concept of Basis of Safety

The concept of Basis of Safety (BOSS) is integral to process safety management, focusing on understanding and mitigating risks to ensure safe operations. It involves a systematic approach to identifying why and how a particular operation can be considered safe. This is crucial in preventing incidents such as explosions, fires, and toxic releases in industrial settings.

Key Concepts of Basis of Safety

Understanding the foundational principles of Basis of Safety (BOSS) is essential for implementing effective safety measures in any industry. These key concepts provide a structured framework that can be adapted to various operational environments, ensuring comprehensive risk management.

To ensure a solid foundation in safety, consider fundamental elements that constitute a robust BOSS methodology:

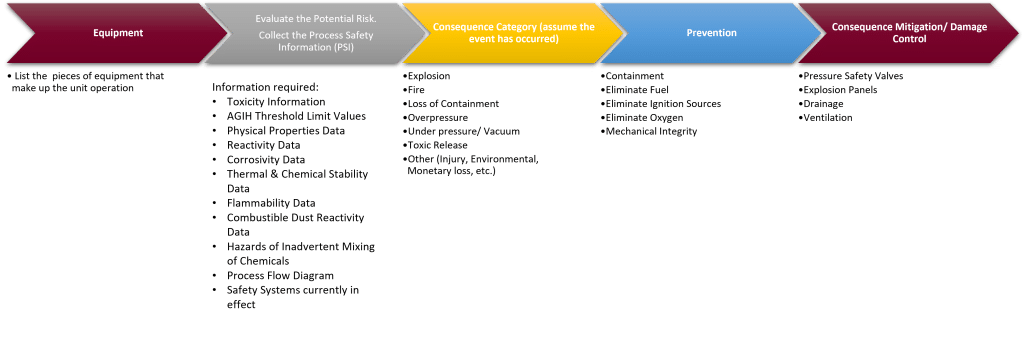

Risk Assessment: A core component of BOSS is assessing risk, which is defined as the product of the likelihood of an event occurring and its potential consequences. This assessment helps in identifying high-risk scenarios that require mitigation measures to bring the risk to a tolerable level.

Mitigation Measures: Once risks are identified, appropriate measures are implemented to reduce either the likelihood or consequences of potential incidents. For example, using inert gas blanketing in a process vessel can prevent fire or explosion by reducing the likelihood of ignition.

Decision Making: Decision-makers must prioritize safety by considering acceptable levels of risk and implementing cost-effective safety measures. This involves making informed choices about resource allocation to address higher-risk areas first

Basis of Safety (BOSS) and Hazard and Operability Studies (HAZOP)

Both are important methodologies in process safety management, but they differ in several key aspects:

- Equipment-Centric: Focuses on the equipment rather than process scenarios.

- Consequence-Based: Begins with the assumption that a consequence has occurred.

- Safeguards and Mitigations: Identifies necessary safeguards and mitigations to prevent or control consequences without relying on guide words or scenarios.

- Risk Acceptance Recommendations: Provides recommendations to meet the company’s risk acceptance criteria.

While BOSS establishes the fundamental safety requirements and strategy for a process or facility, HAZOP is a more detailed, systematic examination of potential deviations and their consequences within that broader safety framework. Both methodologies are complementary and play crucial roles in ensuring comprehensive process safety management.

Basis of Safety & EHS Hierarchy

Implementing a Basis of Safety (BOSS) and adhering to the Environmental, Health, and Safety (EHS) hierarchy of controls are intrinsically interconnected and mutually reinforcing strategies. Both frameworks prioritize inherent safety principles that seek first to eliminate or significantly reduce hazards at their source. This involves designing processes, equipment, and procedures in a manner that foremost avoids or minimizes risk.

Effective safety management starts with inherent safety. This involves eliminating hazards or substituting hazardous materials with less hazardous ones. When elimination isn’t possible, controlling or mitigating hazards through modifying processes to operate under safer conditions are common inherent safety measures that align with the highest echelon of the EHS hierarchy: elimination, substitution, and engineering controls.

Engineering controls further fortify these strategies by focusing on isolating people from hazards through design enhancements. Examples include incorporating fail-safe mechanisms, protective barriers, and improved ventilation systems, which serve as critical safeguards in both BOSS and EHS frameworks.

Safety studies can be conducted using quantitative or semi-quantitative methods. For semi-quantitative studies, a risk matrix and a detailed assessment of the probability of failure on demand for safeguards and mitigations are necessary.

Core Principles of Basis of Safety (BOSS)

Basis of Safety goes beyond simply complying with regulations, aiming to establish a comprehensive understanding of why and how a particular operation can be considered safe.

The core principles of BOSS revolve around:

- Inherent Safety is achieved by eliminating hazards from the process and substituting hazardous materials with less dangerous alternatives.

- Implementing Engineering Controls by designing measures like containment systems to properly manage and reduce hazards.

- Establishing Administrative Controls by developing and enforcing procedures and policies to manage safety. However, it’s important to note that these measures are generally considered less effective compared to engineering controls.

- Personal Protective Equipment (PPE) to shield individuals from hazards.

- Establishing Standard Operating Procedures (SOPs) and following procedures to ensure safe operation.

Components of a BOSS Study

The components of a Basis of Safety (BOS) study start with cataloging the equipment that constitutes the unit operation. Once the equipment is identified, a team with expertise in the process is formed. This team should include at least one facilitator who is trained in the Process Hazard Analysis (PHA) method.

Implementing a robust Basis of Safety (BOSS) framework is not just a regulatory requirement, it’s a vital strategy for ensuring the safety and sustainability of industrial operations. By emphasizing inherent safety principles, engineering controls, and comprehensive risk assessment, BOSS empowers organizations to proactively manage risks and prevent incidents. As industries continue to evolve, so too does the necessity for effective safety management. We encourage you to explore how adopting the BOSS methodology can enhance your safety practices and drive operational excellence. Be sure to check out our next blog post “Basis of Safety (BOSS): Equipment Risk/Exposure” , where we will examine practical case studies that highlight successful BOSS implementations across various industrial contexts.

You can also watch our webinar on the Basis of Safety—Equipment Risk & Exposure here: https://www.youtube.com/watch?v=ul1GGXoAw6w