How To Prevent and Mitigate Combustible Dust Hazards

Combustible dust hazards pose a significant risk across various industries, from manufacturing plants to food processing facilities. When particles are finely dispersed in the air at optimal concentrations, they can cause massive explosions and fires. Protecting people and facilities requires strong measures to prevent and reduce the risks associated with combustible dust.

In this technical blog post, we’ll focus on preventing and mitigating combustible dust hazards by implementing a comprehensive strategy that addresses these hazards at their source, housekeeping best practices, an in-depth look at controlling ignition sources, and various explosion protection measures.

The following informational sections can be found in this article:

You can explore our accompanying blog post, “How To Recognize Combustible Dust Hazards,” to learn more about identifying whether your material is combustible or explosible through laboratory testing and discover how Dust Hazard Analysis (DHA) assists in identifying and mitigating these hazards.

How can we address combustible dust hazards at their source?

When considering the management of combustible dust hazards, prevention emerges as the foremost priority. Addressing potential risks at their source is key to mitigating the likelihood of incidents. The first line of defense revolves around controlling the elements conducive to combustion: fuel, oxidants, and ignition sources.

The following framework outlines the elements that contribute to the initiation and propagation of combustible dust fires and explosions and the appropriate controls:

Control of Fuel: Implement rigorous good housekeeping practices to reduce the accumulation of combustible dust on surfaces, particularly floors.

Control of Oxidant: Aim to eliminate or minimize the presence of oxidants, especially in large-scale operations where controlling oxygen levels may be challenging. This requires thorough discussion and strategizing.

Control of Ignition Sources: Employ measures to prevent self-heating and spontaneous combustion of materials. Identify and mitigate potential ignition sources to minimize the risk of combustion.

Explosion Protection: In cases where preventive measures may not suffice, prioritize the installation of explosion protection equipment and detection systems to safeguard personnel and assets.

How can we control explosible dust clouds?

When addressing the risk of combustible dust explosions, effective management hinges on controlling the formation and dispersion of dust clouds. Achieving this requires a multi-faceted approach to minimize dust escape from process equipment, implement local exhaust ventilation systems, establish comprehensive housekeeping programs, and maintain dust concentrations below critical levels.

Minimize Escape of Dust from Process Equipment: Emphasize proper design, operation, and maintenance practices to prevent the release of combustible dust into the surrounding environment. This entails meticulous attention during the design phase to incorporate safety measures and ensure all equipment is adequately ducted. Conducting Preliminary Hazard Assessments during the initial stages of operation planning can help to identify potential hazards, evaluate risks, and implement control measures to prevent dust release. Reviewing drawings and collaborating with safety experts can pinpoint potential areas of concern, and necessary measures can be implemented to minimize dust escape from equipment.

Implement Local Exhaust Ventilation: Recognizing that complete containment of dust within equipment may not always be feasible, especially in dynamic operations where materials are transferred or processed, deploy local exhaust ventilation systems. These systems effectively capture released dust, channeling it into dust collectors or filter receivers designed for containment.

Establish Good Housekeeping Programs: Institute a robust housekeeping regimen to minimize dust accumulation within the facility. This program should include regular cleaning schedules and protocols to prevent dust buildup on floors and surfaces. A general rule is to maintain dust accumulation levels below 1/32 inch to prevent area classification issues.

Maintain Dust Concentrations Below Critical Levels: Adhere to guidelines to minimize dust concentrations below the Minimum Explosible Concentration (MEC) whenever feasible. This involves diligent monitoring and control measures to keep dust levels as low as reasonably achievable.

Housekeeping Best Practices: Preventing Combustible Dust Hazards (Ref. NFPA 654)

With regards to housekeeping to prevent combustible dust hazards, careful consideration of methods is crucial, especially in areas prone to dust accumulation. Surfaces should be cleaned in a manner that minimizes the risk of generating a fire or explosion hazard. Vacuuming is the preferred method. Choosing vacuum cleaners designed specifically for industrial settings is essential to avoid potential ignition sources.

A cautionary tale highlights the dangers of using household vacuum cleaners, as witnessed in a company where such a cleaner caused fire and explosion incidents. We recommend using Class II Division 2 vacuum cleaners as provided by Nilfisk, PrestiVac, Goodway, and Larson Electronics to name a few, which offer various explosion-proof options to choose from.

Start by using non-static brooms and sweeping tools to collect the bulk of the material. Then, deposit it into conductive or static dissipative bonded and grounded containers. If water washdown is chosen, ensure all electrical equipment is safely powered off to prevent electrical shorts. Avoid using water on aluminum surfaces to prevent the generation of hydrogen gas, which could lead to a different form of explosion.

Blowdowns employing compressed air or steam can be employed to clean surfaces that are difficult to reach or where other cleaning methods present higher risks to personal safety. While compressed air can be useful for cleaning hard-to-reach areas after initial cleaning with vacuuming or washing, it’s imperative to eliminate all possible ignition sources beforehand.

Preventing Deflagration: Limiting Oxidant Concentration (Ref. NFPA 69)

Preventing deflagrations and reducing the concentration of oxidants are critical for maintaining a safe and controlled work environment, especially in industries where dust explosions are a potential hazard.

Deflagration is effectively prevented by maintaining an oxidant concentration below the Limiting Oxidant Concentration (LOC) through the replacement of oxidants with inert gases. Reducing oxygen concentrations by introducing inert gases such as nitrogen, carbon dioxide, and argon into the system effectively displaces oxygen, lowering its concentration.

The LOC varies depending on the nature of the fuel and the specific inert gas used and is performed in accordance with the requirements of the American Society for Testing and Materials (ASTM) E2931. To ensure effectiveness, it is vital to determine the Limiting Oxygen Concentration (LOC) of the material in question.

Maintaining oxygen concentrations below this limit, with an additional safety margin typically recommended, significantly reduces the risk of deflagration incidents. Sigma-HSE offers lab testing services to determine the Limiting Oxygen Concentration (LOC), aiding in implementing effective prevention measures.

Controlling Ignition Sources

In industrial settings, many potential ignition sources require careful control measures. Common ignition sources encompass various activities and phenomena. These include open flames, a direct and obvious hazard, alongside the intense heat generated during cutting and welding operations. Smoking materials like cigarettes or matches pose an avoidable but significant risk if used within the facility, as witnessed in instances where carelessness led to hazardous incidents.

Mechanical processes, such as friction heating or sparks, can ignite combustible materials, highlighting the importance of vigilance during operations. Additionally, high-temperature surfaces, spontaneous self-heating of certain materials, and sparks generated by impacts all contribute to the array of ignition sources present.

External factors like lightning strikes can introduce unpredictable ignition hazards, warranting comprehensive safety measures. Electrical equipment presents separate risks, with arcs and stray currents capable of igniting flammable substances. The impact of electromagnetic radiation, including infrared and ultraviolet wavelengths, cannot be overlooked, particularly in sensitive environments. And, accumulated electrostatic charges can discharge, posing ignition risks in combustible atmospheres.

Addressing these diverse sources requires sound policies, procedures, and training to effectively mitigate the potential for ignition-related incidents. By implementing preventative measures and fostering a culture of safety consciousness, facilities can safeguard against ignition hazards and promote a secure working environment.

Controlling Friction & Impact Sparks

Effectively managing friction and impact sparks is crucial to mitigating fire and explosion hazards within industrial settings. It is imperative to conduct regular inspections and maintenance on plant equipment to prevent overheating caused by bearing failure, misalignment, or rubbing. Properly maintaining conveyor belts, motors, and other mechanical components is essential to avoid potential ignition sources.

Another important consideration is the potential introduction of foreign materials into the system, which can pose ignition risks. Installing appropriate separators or metal detectors can help prevent the entry of such materials, reducing the likelihood of friction-induced ignition hazards. It is especially important to avoid returning floor sweepings to machinery if they contain objects that could cause friction. This simple yet effective measure helps minimize the risk of sparks in the workplace.

When conducting welding, cutting, or other hot work operations, adherence to a hot work permit system in accordance with NFPA 51B guidelines is essential. This system helps ensure that such operations are performed safely, reducing the risk of ignition incidents.

Finally, proactive measures should be taken to prevent the formation of dust clouds and to remove dust deposits regularly. This helps mitigate the risk of dust explosions, which can be triggered by friction and impact sparks.

Controlling Self-Heating

Self-heating poses a significant hazard, particularly in industries dealing with combustible materials like wood or coal. This occurs when the temperature of a substance rises to a point where the heat generated by exothermic reactions surpasses heat losses. In some instances, materials can self-ignite without an external ignition source, emphasizing the importance of understanding factors such as the nature and dimensions of the material, which significantly influence the onset temperature of self-heating.

Determining this critical temperature typically involves laboratory tests simulating process conditions. By knowing this threshold, measures can be taken to ensure that the process temperature remains below the onset temperature, effectively mitigating the risk of self-heating incidents. Vigilant monitoring and control of process conditions are essential to prevent self-heating incidents.

Sources of Electrostatic Charge Generation

Electrostatic discharge presents a unique challenge in industrial environments due to the capability of various operations to generate it. One primary source is the human body itself, which can accumulate energy and discharge it upon contact, posing a significant ignition risk in areas with combustible dust or gases.

Walking on insulating flooring without proper grounding can also lead to electrostatic discharge. To mitigate this risk, personnel can wear conductive/static dissipative shoes or waistbands connected to grounding strips.

Numerous industrial processes also contribute to electrostatic charge generation, including powder sieving, pouring, auger or screw-feed transfer, grinding, micronizing, and pneumatic conveying. Even moving equipment parts, such as rubber surfaces on wheels, can generate electrostatic discharge, emphasizing the need for strong safety protocols and measures.

Controlling Electrostatic Hazards

Accumulating static charges in a process environment poses inherent risks that necessitate proactive mitigation measures. One strategy involves grounding isolated conductors, a process essential for dissipating static charges. Grounding, often referred to as earthing, entails bonding conductive objects to the ground, ensuring they maintain zero electrical potential.

A resistance of <106 ohms is generally estimated to be adequate for effective grounding. In an all-metal system, resistance in continuous ground paths typically remains <10 ohms, ensuring electrical safety.

Achieving effective bonding and grounding requires meticulous identification of conductive equipment and objects within the process, followed by periodic inspection and testing of bonding and grounding systems to uphold their efficacy and mitigate electrostatic hazards effectively.

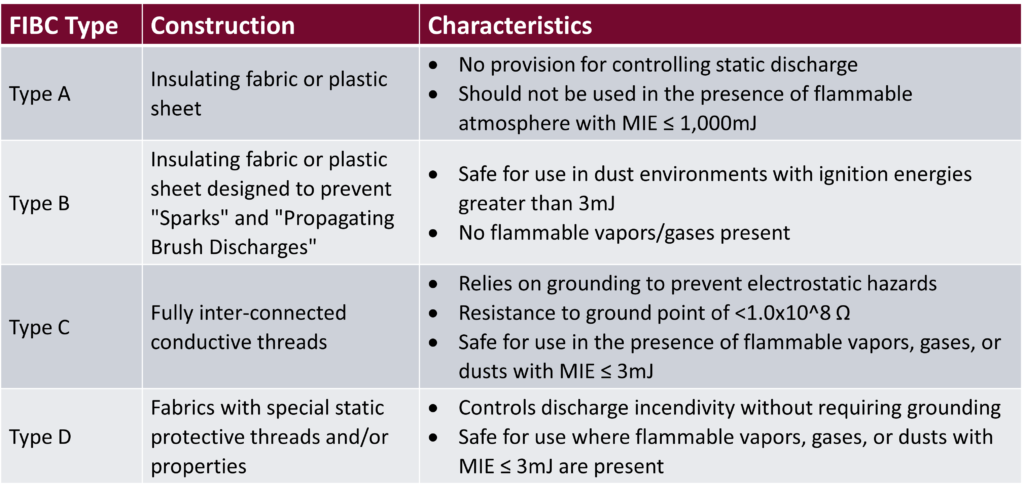

Flexible Intermediate Bulk Container (FIBC): Characteristics and Types

Flexible Intermediate Bulk Containers (FIBCs) are widely used in industries for transporting and storing bulk materials. Understanding the different types of FIBCs and their characteristics regarding static discharge control is essential for ensuring safety in various environments.

Below is a table summarizing the key features of each FIBC type, including construction and suitability for use in different conditions based on static discharge prevention measures and the presence of flammable substances.

Controlling Electrical Arcs

When addressing the control of electrical arcs, it’s essential to consider the equipment being installed in specific areas and its suitability for the environment. The normal operation of many electrical devices can generate arcs, sparks, and hot surfaces, which pose potential ignition sources.

Failures in electrical equipment can exacerbate these risks, creating additional hazards. Therefore, it’s crucial to select and install electrical apparatus that minimizes the risk of ignition. Hazardous (Electrical) Area Classification provides guidance for equipment selection, with classifications defined under Article 500 of the National Electrical Code (NFPA 70).

The purpose of Article 500 is to ensure that electrical equipment does not act as ignition sources in environments with a risk of ignition. Additionally, NFPA 499 offers recommended practices for classifying combustible dusts and hazardous locations for electrical installations in chemical process areas, further aiding in the safe deployment of electrical equipment.

Hazardous Electrical Area Classification

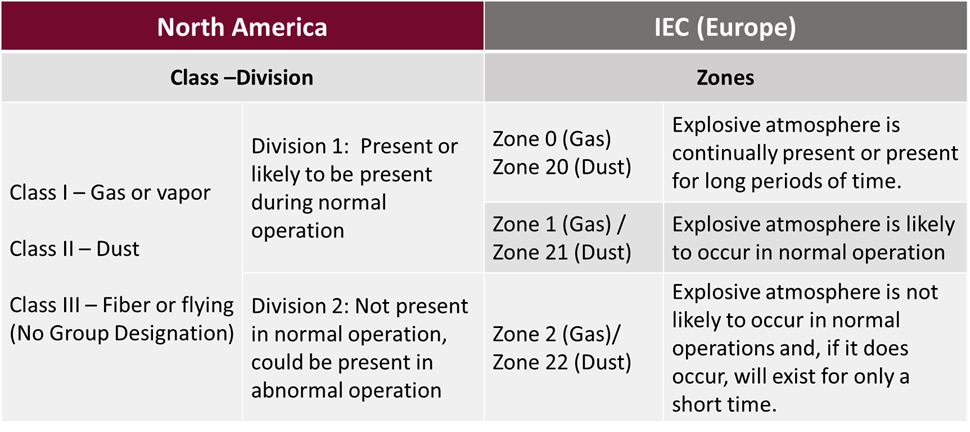

A Hazardous (Electrical) Area Classification (HAC) aims to proactively assess and manage the risks associated with electrical equipment in potentially hazardous environments. The table below outlines the different classifications primarily used in North America.

These classifications are comprised of three main classes and two significant divisions. Class one typically denotes gases or vapors, whereas class two pertains to fibers or airborne particles.

The divisions are categorized into Division One, which involves operations where explosive atmospheres are present under normal conditions, and Division Two, where such atmospheres are not normally present but might occur under abnormal circumstances.

Within these divisions, Zones 0, 1, and 2 are primarily designated for gases and vapors, and Zones 20, 21, and 22 are primarily designated for dust.

Zones 0 and 20 indicate areas where explosive atmospheres are continuously present or present for extended periods.

Zones 1 and 21 signify areas where such atmospheres could occasionally occur during regular operations. In contrast, Zones 2 and 22 denote areas where explosive atmospheres are not expected under typical conditions but could arise due to abnormal situations.

Comprehending these classifications and divisions is vital for ensuring the proper implementation of safety measures across various industrial and hazardous environments.

Explosion Protection Measures

In operational settings where preventative measures such as controlling fuel, oxidants, and ignition sources may not suffice to mitigate explosion risks, the focus shifts to safeguarding assets and personnel through proactive explosion protection measures. Understanding how to shield oneself in the event of an explosion is extremely important and involves considering various protective measures:

Explosion Venting to a Safe Place (NFPA 68): Directing explosion forces to a designated safe area helps minimize damage and reduce risks to personnel.

Explosion Suppression by Injecting a Suppressant (NFPA 69): Utilizing suppressants to quench explosions aids in controlling and mitigating their impact swiftly.

Containment by Explosion-Resistant Construction: Constructing facilities with materials capable of withstanding explosion forces helps contain and minimize the spread of damage.

Explosion Isolation: Implementing isolation systems to rapidly isolate explosion-prone areas from unaffected regions helps prevent escalation.

Explosion Venting (Ref. NFPA 68)

Explosion venting, as outlined in NFPA 68, is a vital mechanism for managing the potential hazards of explosions within process equipment or buildings. It provides a designated outlet for expanding explosion products to escape safely, making it widely recognized as one of the most prevalent forms of explosion protection due to its simplicity and cost-effectiveness.

Its versatile application makes it suitable for safeguarding various equipment such as dust collectors, silos, hoppers, and buildings. However, it is important to consider its limitations, as explosion venting is inappropriate for containing toxic materials, and venting into the interior of buildings is generally deemed unacceptable.

Despite its effectiveness, venting efficiency should be carefully monitored, as the volume of the resulting fireball can significantly exceed the capacity of the vented vessel. Proper disposal of explosion products is critical, with measures ensuring they are directed outside the building to a designated safe location.

Alternatively, flameless venting techniques may be considered to further enhance safety measures. Adhering to these principles and guidelines outlined in NFPA 68 can effectively mitigate the risks associated with explosions, ensuring the safety of both personnel and equipment.

Flameless Venting

Flameless venting offers a sophisticated solution by combining explosion venting with flame-arresting techniques. Typically consisting of a vent panel, flanged housing, and a flame arrestor element, this system functions by opening the vent panel during the early stages of an explosion, thereby relieving the hot gases and pressure from the vented vessel.

Flame propagation beyond the device is effectively prevented through heat dissipation in the arrestor element. This integrated approach ensures enhanced safety measures against explosions while effectively containing and neutralizing potential fire hazards.

Explosion Suppression

Explosion suppression systems are meticulously designed to quickly detect and suppress explosions in their nascent stages, preventing consequential damage to vessels or surrounding infrastructure.

These systems typically consist of a rapid-acting explosion sensor, a sophisticated control system, and pressurized containers of suppressant. Sodium bicarbonate is a commonly used suppressant owing to its effectiveness in neutralizing combustion processes.

Enclosures susceptible to deflagration, including reactor vessels, mixers, blenders, pulverizers, mills, dryers, ovens, filters, screens, and dust collectors, can benefit from the protective capabilities of explosion suppression systems. By promptly mitigating explosion risks, these systems aid in safeguarding personnel, equipment, and facilities against potential catastrophic events.

Explosion Containment

Explosion containment is a significant aspect of process safety management in industries prone to dust explosions. Dust explosions typically reach maximum pressures ranging from 8 to 12 bar, necessitating stringent containment measures.

All components of the equipment, including flanges and covers, must be able to withstand these extreme pressures to prevent catastrophic failures. Maintaining the pressure rating of the equipment throughout its lifetime is paramount to ensuring continued safety.

While certain plant equipment, such as hammer mills, may inherently possess the robustness required for explosion containment, manufacturing larger equipment capable of withstanding such high pressures is often impractical. Unless the equipment is of small volume, achieving the necessary strength to withstand pressures of 8 to 10 bar presents significant challenges in design and fabrication. Therefore, careful consideration and adherence to safety standards are essential in effectively managing explosion containment risks within industrial settings.

Deflagration Isolation – Active (Ref. NFPA 69)

Deflagration isolation, particularly in its active form as outlined by NFPA 69, involves the deliberate interruption or mitigation of flame, deflagration pressures, pressure piling, and flame-jet ignition between interconnected enclosures via pipes or ducts. This proactive approach aims to prevent the spread of explosions from one area to another, thereby containing potential damage and minimizing risks to personnel and property.

Piping, ducts, and enclosures protected by an isolation system must adhere to stringent design standards to ensure they can withstand the estimated pressures specified by the manufacturer. By implementing vigorous isolation measures, industries can enhance their safety protocols and effectively mitigate the potential consequences of deflagration events.

Preventing and mitigating combustible dust hazards is paramount for ensuring the safety of personnel and facilities in various industries. Companies can effectively manage the risks associated with combustible dust by implementing robust measures, conducting thorough analyses, and adhering to safety standards such as those outlined by NFPA.

From strategies for controlling explosible dust clouds to best practices for cleaning, preventing deflagration, and managing ignition sources, every aspect covered in this blog post enhances workplace safety.

At Sigma-HSE, we assist companies with process safety testing to identify hazards associated with combustible dust while conducting a thorough Dust Hazard Analysis (DHA) to help recognize and reduce these hazards proactively.