An Electrostatic Hazard Assessment is a systematic process used to evaluate the risks associated with generating, accumulating, and discharging electrostatic charges in various environments. It involves identifying potential sources of electrostatic discharge (ESD) and assessing the likelihood and consequences of such discharges leading to hazardous situations, such as ignition of flammable materials or damage to sensitive electronic equipment.

Electrostatic discharge (ESD) happens when electricity suddenly flows between two objects with different electrical charges. This often occurs when two materials, like liquids or solids, touch and then separate. While the buildup of electrostatic charge itself isn’t usually dangerous, it becomes hazardous when it causes energetic discharges that ignite combustible dust, flammable liquids, or gases.

Common Electrostatic Property Terminology

Conductive Materials

Conductive materials, like metals, are unable to retain an electrostatic charge when grounded. When not grounded, charge accumulation persists, but connecting the material to the ground allows the electric potential to dissipate.

This characteristic makes conductive materials essential for preventing static buildup in situations where discharge is necessary, like handling flammable materials.

Static Dissipative/Antistatic/Semi-Conductive Materials

These materials, like conductive ones, can accumulate charges, but they can release them at a higher rate. Unlike conductive materials which discharge to zero, static dissipative materials release charges gradually, minimising the risk of hazards.

Despite potential residual charge accumulation, it’s typically not significant enough to cause harm or pose a threat to safety.

Nonconductive/Insulating Materials

Materials such as plastics allow charges to accumulate without a means of dissipating them. Even when grounded, the charge remains, making them unsuitable for handling flammable materials. Nonconductive or insulating materials, unlike conductive ones, resist the flow of electric charge.

These materials allow charges to accumulate without dissipating them, making them unsuitable for situations where discharge is necessary. Even when grounded, discharging electrostatic charge from nonconductive materials is challenging due to their inherent properties.

Electrostatic Discharge

Electrostatic discharge refers to the phenomenon where charge equalization occurs between objects with different electrostatic potentials or between a charged object and a grounded one. It manifests as the release of electrostatic energy in various forms such as sparks, brushes, cones, or corona discharge.

For example, when charges equalize between two objects with different electrostatic potentials or between a charged object and a grounded one, electrostatic discharge occurs.

Connecting two metals A and B with a bonding strip facilitates the transfer of charges, thereby equalizing their potentials. Additionally, grounding aids in discharge by transferring charges to the ground, ensuring electrostatic potential equalization.

Bonding & Grounding

Bonding electrically connects adjacent conductive objects to prevent voltage differences, essential for ensuring safety and preventing hazards. Grounding provides a path for electrostatic charges on bonded objects to dissipate to the ground, further minimising the risk of electrostatic discharge incidents.

Under DSEAR in the UK, there are accepted codes of practice that outline how earthing and bonding should be completed in hazardous zones. While these standards can be followed and best practices integrated into a process, how can we ensure that safety systems and processes continue to work at their full potential? Download our DSEAR: Earthing & Bonding in Hazardous Areas resource here.

Electrostatic Hazard Assessment – A Systematic Approach

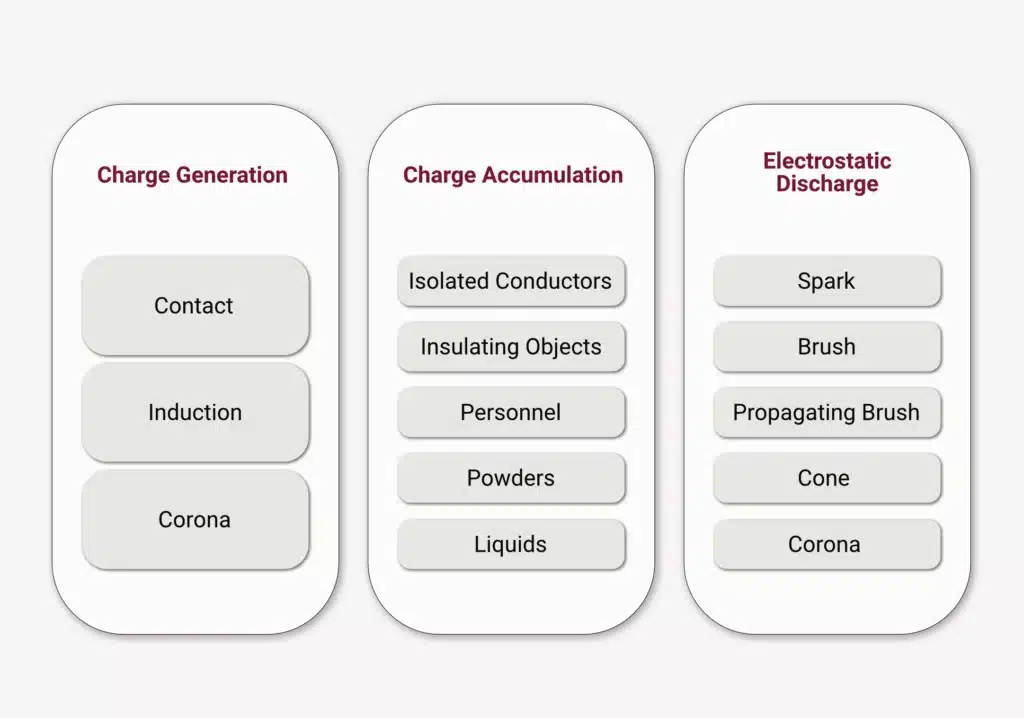

Assessing electrostatic hazards involves a systematic approach. We need to understand how charges generate, accumulate, and discharge, along with key parameters to consider during discharge, such as the potential for ignition. Charge generation occurs through various means. First, contact can transfer a high-charge material to a person upon touch. Secondly, induction induces an electrical current in a conductor by placing it in a changing magnetic field.

Discharge methods include corona discharge, which happens when electrodes at high potential create a current separated by a neutral fluid like air. Charges accumulate on isolated conductors or insulated objects like plastic, as well as on human bodies if they are isolated. Powders and liquids also accumulate charges.

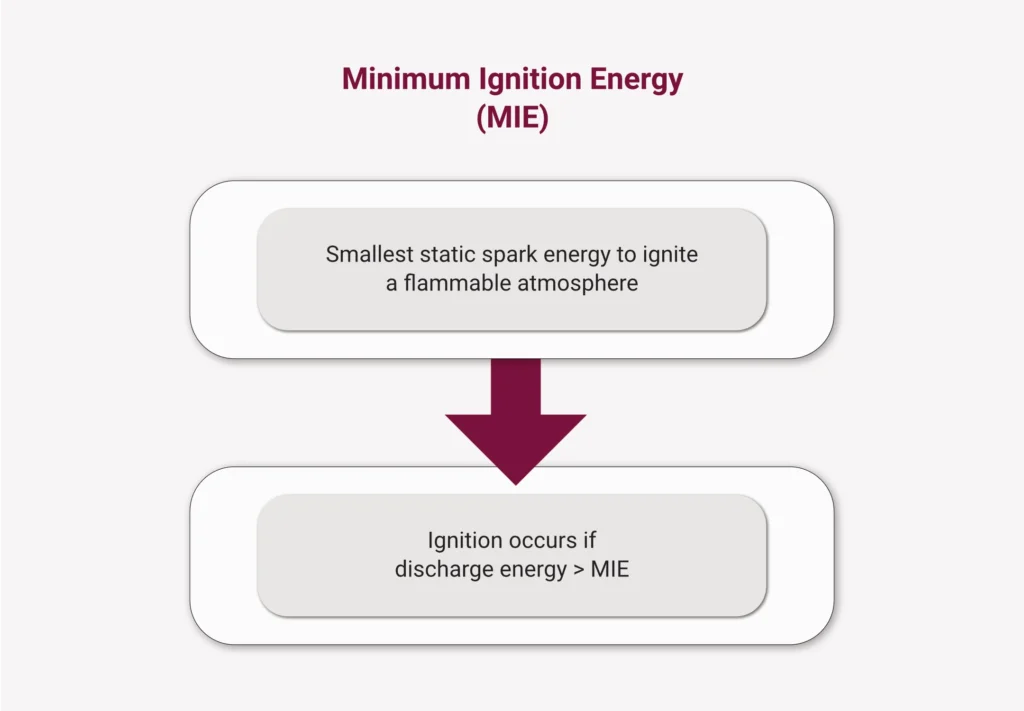

Discharging accumulated charges can manifest as sparks, brush discharges, propagating brushes, cones, or coronas. Understanding key parameters, such as ignition energy, is critical. Ignition energy represents the minimum static spark energy required to ignite a flammable atmosphere. Every material has its ignition energy threshold, below which ignition does not occur. Ignition leading to flash fires or explosions happens if the discharge energy exceeds the material’s Minimum Ignition Energy (MIE).

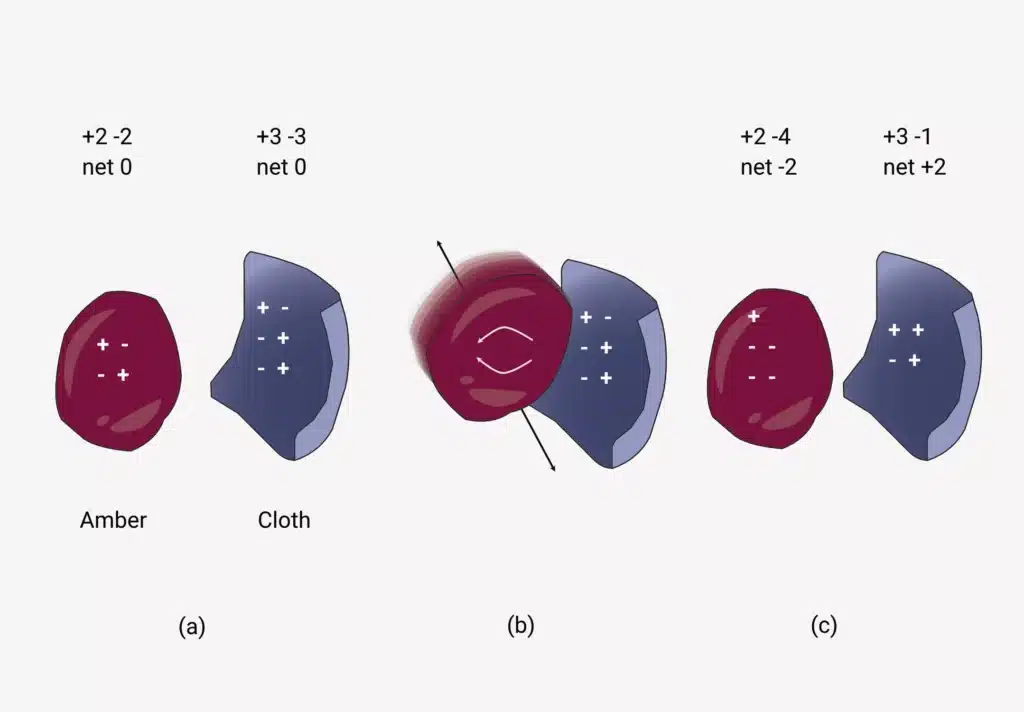

Charge Generation – Contact Charging

An electrostatic charge typically arises when two materials come into contact and then separate, resulting in one material becoming negatively charged and the other positively charged. This buildup of charge can occur on electrically isolated conductors or insulating materials. Ignition may occur if the discharge energy exceeds the Minimum Ignition Energy (MIE) of the flammable atmosphere.

Examples of Electrostatic Charge Generation

Personnel

When individuals walk on floors made of insulating materials, such as rubber or plastic, they can accumulate static charge due to the lack of conductivity in the flooring material. This accumulated charge can then be transferred to the individual.

Similarly, when personnel remove coveralls or other protective clothing while wearing insulating shoes, static charge can accumulate on their bodies. This is because the insulating properties of the shoes prevent the charge from dissipating into the ground.

Powders

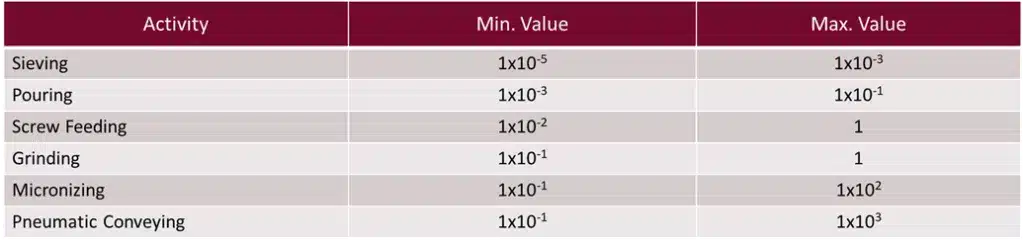

- Sieving: During the sieving process, fine particles rub against each other and the sieve, creating friction that leads to the generation of static electricity. This static charge can accumulate on the surface of the particles and the sieve mesh.

- Pouring: When powders are poured from one container to another, the particles can rub against each other and the walls of the containers, resulting in the generation of static charge.

- Auger or screw-feed transfer: In systems utilising augers or screw feeds to transfer powders, the mechanical movement of the auger or screw can cause friction between the particles, leading to the buildup of static electricity.

- Grinding: Grinding operations involve the abrasion of materials, which can generate static electricity due to the friction between the grinding surfaces and the particles being ground.

- Micronizing: Micronization processes, which reduce particle size to very small dimensions, can also result in the generation of static charge as particles collide and rub against each other.

Liquids

When liquids flow through hoses and pipes, friction between the liquid and the walls of the conduit can generate static electricity. This is particularly common in situations involving fast-flowing liquids or those with high viscosity.

Agitating or mixing liquids can lead to the generation of static charge due to the movement and collision of liquid molecules. During filtration processes, liquids pass through filters or membranes, causing friction that can result in the buildup of static electricity on the surfaces of the filtration media.

Movable Items

Metal carts equipped with rubber or plastic wheels can accumulate static charge as they move across insulating surfaces. This is because the wheels insulate the cart from the ground, preventing the dissipation of static charge.

Types of Electrostatic Discharges

The type and energy of electrostatic discharges depend on various factors such as material resistivity, geometric arrangement, and discharge-initiating electrodes.

- Spark Discharge: This type of discharge occurs between an electrostatically charged conductor (usually metal) and a grounded conducting object. It releases energy in the form of a spark, with the amount of energy stored being determined by the capacitance (C) and voltage (V) squared (½CV2). The energy released in a spark discharge can exceed 1,000mJ and has the potential to ignite various materials, including dust and solvents.

- Brush Discharge: Brush discharge happens between a charged insulator and a grounded conducting electrode. The energy released in a brush discharge is relatively low, typically less than 4mJ. While it may not ignite dust clouds, it can ignite flammable gases and hybrid mixtures.

- Propagating Brush Discharge: This type of discharge occurs on the surface of a charged insulator backed by a conductor. It’s similar to having a capacitor formed by an insulating layer and a conductor. For instance, a metal container coated with insulating paint can create such a capacitor. This phenomenon can also happen inside insulating hoses and pipes. The discharge energy can range from 1,000mJ to 2,000mJ and has the potential to ignite a wide range of materials

- Bulk Brush/ Cone Discharge: This discharge occurs when vessels are filled with highly charged insulating powders. Factors like particle size and vessel diameter influence its intensity, with larger particles and vessels typically generating higher-energy discharges. Gravity transfer of fine powder to grounded conductive drums is not expected to result in energetic Bulk/Cone discharges. The maximum effective energy of bulk brush/cone discharge is approximately 25mJ.

Electrostatic Data/Properties:

Before we assess the risks of electrostatic hazards, we need to gather some important information about the process and the materials we’re working with.

- Minimum Ignition Energy (MIE) of flammable atmospheres (Combustible Dust Lab Measurement): This tells us if a material can catch fire. We find this out through tests in a laboratory.

- Resistance-to-Ground of metal objects in the plant (Onsite Measurement): We measure how well metal objects can let electricity flow through them and into the ground.

- Resistance-to-Ground of operators’ shoes and floors (Onsite Measurement): We measure how well electricity can flow through the shoes and floors of the people working in the plant.

- Volume Resistivity of powders (Lab Measurement): This helps us understand how well powders can resist the flow of electricity.

- Volume Resistivity of hoses (Lab Measurement): This tells us how well hoses can resist the flow of electricity.

- Conductivity of liquids (Lab Measurement): We test how well liquids can conduct electricity.

- Surface Resistivity of containers and liners (Lab Measurement): This tells us how well containers and liners can resist electricity on their surfaces.

- Electrostatic Chargeability of powders and liquids (Lab or Onsite Measurements): We test how easily powders and liquids can build up static electricity, both in a lab and at the actual site

Controlling Electrostatic Hazards – Volume Resistivity

Controlling Electrostatic Hazards involves considering the concept of Volume Resistivity, which is a material property indicating how strongly a substance resists the flow of electric current. Volume Resistivity is measured in ohm-meters (Ω⋅m).

Materials with low Volume Resistivity allow electric current to flow more easily through them. Understanding this property helps in selecting materials that can effectively dissipate electrostatic charges to minimize an prevent static hazards and discharge incidents.

Materials may be classified by their Volume Resistivity as follows:

Controlling Electrostatic Hazards – Electrostatic Chargeability

When dealing with Electrostatic Hazards, it’s important to consider a material’s ability to become charged during handling or processing. This property, known as Electrostatic Chargeability, helps determine how likely a material is to accumulate electric charge.

By understanding this characteristic, we can develop safety guidelines to handle materials safely and reduce the risk of static discharge accidents. Chargeability data is often combined with other material properties to create comprehensive safety measures.

Typical Mass Charge Densities (µC/kg) for Medium Resistivity Powders

Electrostatics pose significant fire or explosion hazard risks in processing environments. This blog post explains various aspects of electrostatic hazards, providing valuable insights into the systematic approach of Electrostatic Hazard Assessment. We explored examples of electrostatic charge generation, different types of electrostatic discharges, and essential electrostatic data and properties.

Additionally, we discussed effective methods for controlling electrostatic hazards, such as utilising volume resistivity and managing electrostatic chargeability.

By understanding these concepts and implementing appropriate measures, we can mitigate the risks associated with electrostatic discharges, ensuring safety in diverse environments.