Our process safety laboratories generate test data on dangerous substances for transportation.

We undertake the following tests:

-

Oxidising Solids – UN Test O.1

-

Readily Combustible Solids or Flammability of Solids (Burning Rate) – UN Test N.1

-

Self Heating Solids – UN Test N.4

Please contact us if you have any bespoke testing requirements.

If your business transports potentially dangerous goods or substances, then you may be subject to a range of national and international transport regulations.

Sigma-HSE’s labs offer customers comprehensive standard and custom testing packages to aid you in the classification and transportation of dangerous goods and materials.

Test your potentially hazardous materials for safe transport

The Sigma-HSE Advantage

Request a Free Quote

Discover our range of UN transportation & classification tests

OXIDISING SOLIDS - UN TEST O.1

Standards & Schedule of Accreditation

Recommendations on the Transport of Dangerous Goods, UN Manual of Test & Criteria – UN Test O.1

Test

Our UK laboratory generates test data for materials that you are looking to transport. The Oxidising Solids – UN Test O.1 is primarily conducted for the purposes of transportation classification of solid substances.

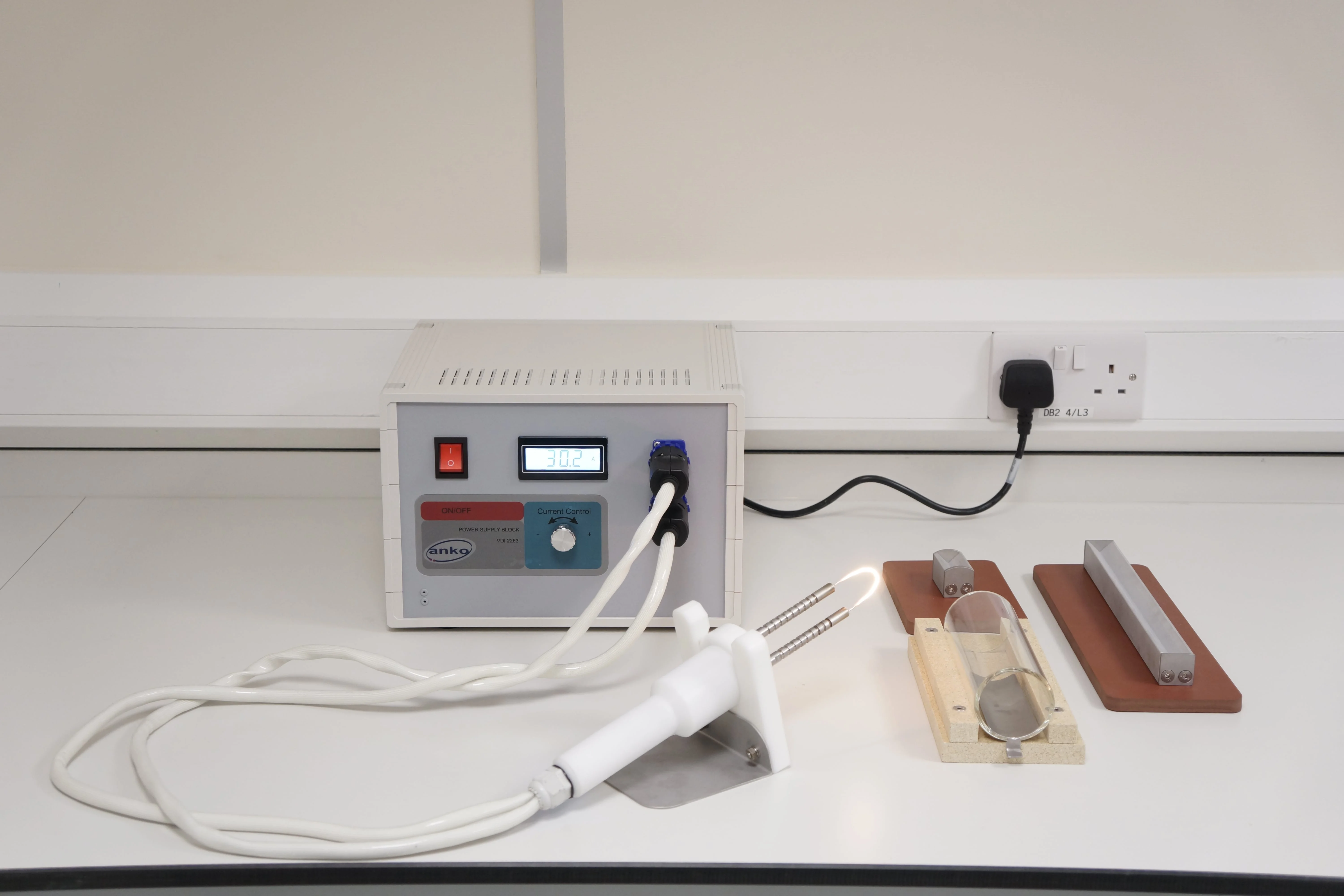

Mixtures of a reference oxidiser (potassium bromate) and fuel (cellulose) and the mixtures of the test substance and cellulose are prepared in specific ratios. Using a conical funnel, the mixtures are formed into a truncated conical pile which is inverted onto a looped ignition wire that rests on a low-heat conducting plate. Power is then applied to the ignition wire and is maintained for the duration of the test.

A recorded burning time is taken from when the power is switched on, to when the main reaction (e.g. flame, incandescence or glowing, spontaneous combustion) ends. This test is performed on each ratio five times.

How can UN Test O.1 data help?

Materials and substances that are classified for transportation alongside oxidizing substances are usually based on either guesswork or comparative studies. These are often incorrect and large costs associated with sustainable transport with classified oxidised substances and materials can be avoided. If a product contains a known oxidising constituent, it doesn’t simply mean the product blend should also be classified. Often the product as a whole, is found, through testing not to be.

SELF HEATING SOLIDS – UN TEST N.4

Standards & Schedule of Accreditation

Recommendations on the Transport of Dangerous Goods, UN Manual of Test & Criteria – UN Test N.4

Test

The test is conducted to determine whether a solid material should be classified as a Self-Heating Solid of UN Class 4, Division 4.2. The same test technique applies to classification under CLP as a Self-Heating Solid (H.251 & H.252).

The sample, in its commercial form, is filled to the brim of the test basket and the basket is tapped several times. More material is added, if the material is seen to have settled. The test basket is housed in a wire mesh cover and placed into the centre of a preheated, hot air, circulating oven, set to the required test temperature.

The initial test is conducted using a 100 mm basket, at a temperature of 140 °C. The sample temperature and oven temperature are continually monitored, using inconel sheathed thermocouples over a test period of 24 h (unless ignition is detected earlier). If ignition is not observed, then the material is not classified as a self-heating solid. If ignition is observed, then the material is classified, and further testing is required to designate the correct packing group and/or define the classification exemption conditions.

Self Heating Solids – UN Test N.4 Benefits

Although the material may be a self-heating substance, if transported within specified volume restrictions, exceptions can be made and therefore huge costs are avoided. These exemptions can only be determined through testing.

READILY COMBUSTIBLE SOLIDS OR FLAMMABILITY OF SOLIDS (BURNING RATE) - UN TEST N.1

Standards & Schedule of Accreditation

Recommendations on the Transport of Dangerous Goods, UN Manual of Test & Criteria – UN Test N.1

Test

The Readily Combustible Solids or Flammability of Solids (Burning Rate) – UN Test N.1 is conducted to determine whether a solid material should be classified for transportation as a flammable, or readily combustible, substance of UN Class 4, Division 4.1. The same test technique is used for the classification of CLP as a Flammable Solid (H.228)

A powder train strip is formed using a triangular cross-sectioned mould onto a heat-resistant, non-porous plate. Using a butane flame, one end of the powder train the strip is ignited and an initial time taken to burn over a marked 200 mm length is recorded.

If the burning rate test time is equal to, or less than 120s, then further trials are conducted over fresh powder strips. The burning time and burning rate test over a length of 100 mm are measured.

Understanding Readily Combustible Solids or Flammability of Solids (Burning Rate) – UN Test N.1

If the time taken is equal to or less than 45 s (2.2 mm.s-1) then the material is classified as a Flammable or Combustible Solid, of UN Class 4, Division 4.1. During the 100 mm trials, a section of the material past the 100 mm mark is subjected to wetting and observations are made to whether the wetted zone, stops flame propagation for at least 4 minutes.

If the wetted zone fails to stop propagation, the material is designated to Packing Group II. If it succeeds in stopping propagation, a Packing II group III designation is given. The preliminary screening test method is identical to that detailed within CLP/GHS’ regulatory requirements and procedures and therefore, the test data as gathered and carried out by the preliminary screening test can be used for both applications.