Local Extraction Ventilation (LEV) systems provide air suction at a specific location(s) in the workplace, to remove hazardous substances away from where they are generated. The idea is to ‘collect and contain’ the hazard in a safe place. In this way, the employees can be kept safe and the workplace can comply with health and safety regulations.

LEV systems can be for solid particles (dusts), mists, vapours, fume or a combination of these. (The particles generated from welding or soldering are extremely small and are referred to as ’fume’.)

As a starting point, it is important to know the legal parameters that govern your specific hazard. The ‘COSHH Essentials’ tool is a good start if operators are in the immediate vicinity and might inhale toxic substances. Good information can also be found in INDG408 Clearing the air or HSG258 ‘Controlling airborne contaminants at work’.

If the hazard is flammable, your workplace would be subject to the Dangerous Substances and Explosive Atmospheres Regulations (DSEAR). LEV systems might be required to make sure the flammable substance doesn’t come into contact with anything that could ignite it.

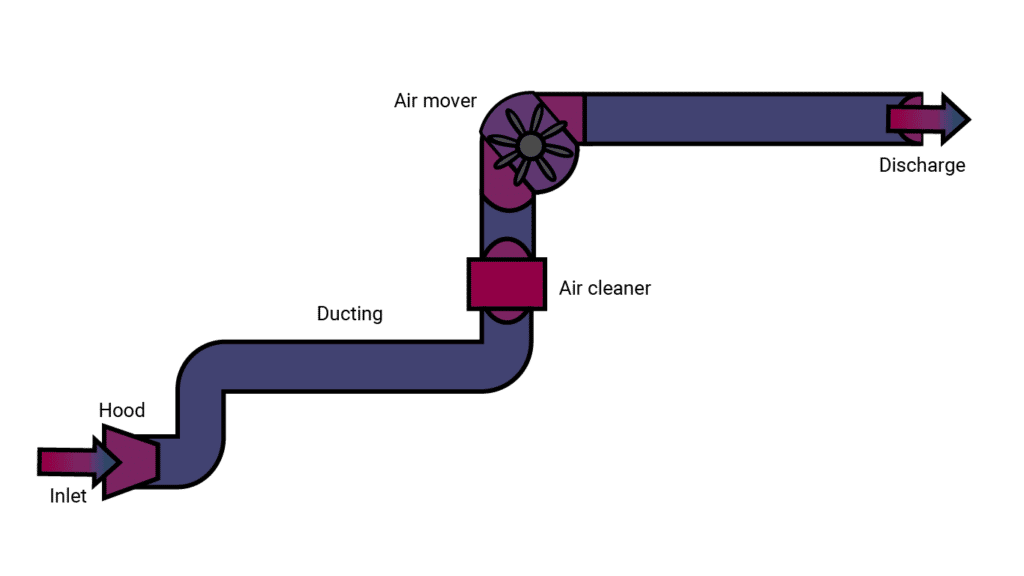

All exhaust ventilation systems have components which need to be correctly designed for the specific nature of the hazard and how it is generated. These are illustrated below:

Figure 1: Common elements of a simple LEV system.

LEV Systems and their Elements

Hood

The capture hood is the containment system to ‘catch’ the dust or vapour from where it is generated. If the hazard tends to float up, a canopy hood would be suitable. If there is wood dust that comes off a sanding machine, it is probably concentrated in a particular direction and some kind of ‘built-in’ hood might be best. This is called on-tool extraction. The capture hood has to be effective, but also fit in with the existing spatial set-up. If the area is cramped, the capture hood would need to fit in with what is there. If dust is a valuable product, one would want to minimize waste. On the other hand, if the dust is extremely toxic and flammable, complete capture is important.

Ducting

The ducting contains the contaminated air as it moves away from where it is generated. It is important that there is enough air movement to stop dust from depositing in the ducts, which could become clogged and impede the system’s efficient operation. Similarly, flammable or harmful vapours need enough momentum to not return to where they came from. Velocity (m/sec) in the ductwork is the crucial parameter. Non-condensing gases would need just 5m/s, while dust may need around 20m/s to stay suspended in the air.

Filter

The filter (air cleaner) cleans the air before it is vented to the atmosphere (or recirculated to the workplace). Broadly speaking, filters are designed to remove particles (dust) or vapours. If there is a combination of both, a dual filter system may be needed, removing the dust first and then the vapours. The performance of the filter is largely dependent on the surface area available. To maximize surface area, cartridge filters are pleated and then arranged into several tubes where the air flows from the outside of the tube (dirty side) to the inside (clean side). The number of cartridges determines the capacity of the system. Most industrial dust collectors use this arrangement.

For smaller scale systems and where costs need to be minimised, a bag filter may be used. For tight spaces, a bag filter might be the only option. In this case, the air simply passes through an upside down cloth bag. The bag is held aloft by the air flow moving from the inside to the outside of the bag. The dust is trapped on the inside of the bag and falls down into a collection bin.

Surface Area Filtering

The surface area for filtering is much less because there is no pleating and the finest dust fraction often passes straight through the bag with the exhaust air. This can be problematic, because the fine dust fraction will eventually settle- resulting in layers of fine dust in the workplace. This is often on high surfaces that are difficult to reach and keep clean. If these fine dust layers are allowed to accumulate, it can be a serious fire hazard. If there is any small explosion or vibration, the settled dust will become airborne and the cloud can be highly flammable. If ignited, this suspended fine dust leads to a secondary dust explosion. Almost all of the most serious dust explosions causing loss of life and property have been secondary dust explosions.

In some applications, such as industrial spray booths, the filter needs to cover a fairly large flat surface, effectively a filter ‘wall’. In this case, a plain pleated filter is used.

Organic solvent vapours can be hazardous to operator health and safety, and can also be flammable. Organic vapours can be removed by an activated carbon filter. This filter is easily blocked by particulates, so a particle pre-filter is usually used. It is important that this prefilter is kept clean. The carbon filter needs to be replaced or reactivated at regular intervals.

Fan

The fan (air mover) needs to provide enough suction to keep dust suspended and to move vapours away from where they are generated. The electrics of most fans pose a potential ignition source, and if the tip speed is high, it can generate an electrostatic charge, which can also be incendiary. To reduce the risk of igniting a dust cloud, the fan is usually positioned on the ‘clean’ side of the filter. If the dust is flammable, a fan on the dirty side is a dangerous idea. Aside from the fact that the fan will need to be ATEX rated for zone 20 or 21, which is expensive, any metallic objects entrapped in the airflow could spark against a fan blade and ignite the dust cloud. Even if the dust is not flammable, hard objects can damage the fan blades.

Discharge

The air leaving the fan from the discharge should be clean and pose no explosive risk. Although unlikely, it is possible that the filter has ruptured, in which case the exhaust air might be laden with potentially explosive dust.

Filter Cleaning

Over time, dust will accumulate on the ‘dirty’ side of the filter forming a filter cake. Ideally, this filter cake will simply drop down into the collection bin, but if the cake is allowed to build up, the filter will become clogged and will need to be cleaned regularly to be effective. Although this is sometimes done manually by a shaker system, if there is compressed air on site the most efficient way to clean filters is to pass a short pulse of compressed air in reverse flow from the clean side towards the dirty side. This is referred to as reverse flow pneumatic pulse cleaning. The pulse is repeated every few seconds and the frequency of this pulse will vary depending on how much dust accumulates and how ‘sticky’ the dust is. In larger dust collectors with several cartridge filters, the compressed air pulses through each cartridge one by one every few seconds to dislodge the filter cake. As the cake is dislodged, the dust forms a concentrated cloud, which then settles into the collection bin. When the pulse passes continuously from one cartridge to the next, a dust cloud is continuously present above the bin. If the dust is explosive, the cloud is explosive and it is important to avoid any source of ignition.

Cyclone-Filter Combinations

Some dusts are more explosive than others. Smaller particles are always more explosive than larger ones, and a mixture of large and small dust particles is safer than if the larger particles are removed. A cyclone is often used to remove larger particles before the air stream enters the filters of the dust collector. Although this reduces the dust load on the filters, this practice can be dangerous in that it concentrates the finest dust to one place and the explosion risk in the dust collector would increase.

Ignition Sources

There have been several incidents where a dust collector explodes. Hot metal particles can enter the ducting as a spark and ignite the dust cloud. Spark traps are important to prevent this. A spark trap forces incoming air to increase its velocity through a tortuous route, which extinguishes a potential spark.

There might also be an ignition source that creeps in while emptying the dust bin or a mechanical spark. This could be as simple as accidentally dropping the bin, which would create a dust cloud as well as the spark to ignite it. If the dust is very sensitive to explosion (including metal dust), there may be a static charge that builds up across the filters and the cloud could ignite when the charge equalises. Even when ignition sources are rigorously excluded, there must be some provision to mitigate an explosion- if an explosion happens, the idea is to protect lives and minimize injury.

Explosion Hazards Mitigation

If the dust collector explodes, it could spread back to the workplace and cause serious injuries. An explosion isolation valve contains a flap that is forced closed when there is sudden air flow in the reverse direction. This explosion valve needs to be correctly sized to the expected flow and flammability properties of the dust in question.

Unless the dust collector is pressure rated, an explosion will vent through the weakest place in the structure. An explosion plate is designed to be the weakest point of the structure and should be blown off to direct the explosion in a safe direction. This should be away from walkways, often directed vertically upwards. The explosion plate needs to be on the dirty side of the filter and carefully designed- it should be large enough to vent the explosion effectively, and the pressure rating needs to match the maximum expected pressure from the specific type of dust. If the pressure rating of the explosion plate is too high, the explosion may not dislodge it, venting instead in another, potentially dangerous direction.

Off-the-shelf Dust Collectors

If a dust collector is bought ‘off the shelf’, and your dust is flammable it might be a waste of money. Some off-the-shelf systems include an explosion plate- and on this basis, sold as explosion proof. This is simply false. The explosion plate needs to be carefully sized to suit the specific explosion characteristics of the dust, and the fan, even if positioned on the clean side of the filters, will need to be ATEX rated for zone 22. If your dust is highly flammable (most metal dusts, especially aluminium), the filters may need to be anti-static to prevent a build-up of electrostatic charge.

Summary

The best way to specify a dust collector and avoid resulting explosion hazards is to characterize the flammable properties of your dust. Sigma-HSE has state of the art equipment and highly skilled technicians to provide essential data for designing your LEV system Sigma-HSE can also partner with your technical team to ensure you are DSEAR compliant and all findings are integrated with your LEV system design.