Layer Ignition Temperature (LIT) Testing

CONTACT US

CONTACT USOur UK laboratory generates flammable & explosive test data for your combustible dust and powders. Th layer ignition temperature test determines the lowest temperature at which a heated surface will ignite combustible dusts or powders when settled as a dust layer.

The Sigma-HSE Advantage

Request a Free LIT Quote

Frequently asked questions

What are your Standards & Schedule of Accreditation

BS EN ISO IEC 80079-20-2 to the standards before BS EN 50281-2-1 / ASTM E1491

What is the Layer Ignition Temperature (LIT) test?

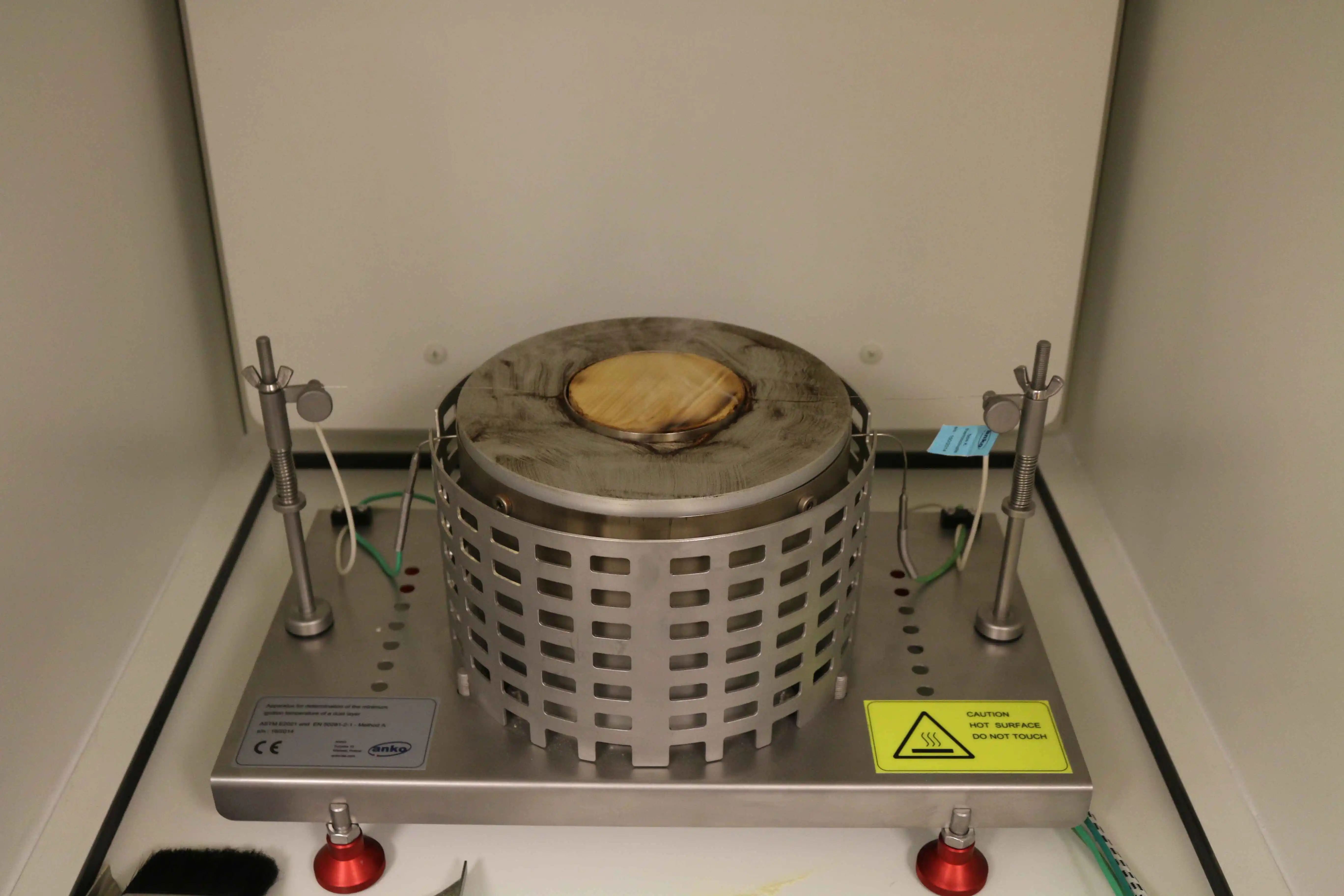

The Layer Ignition Temperature (LIT) test is conducted to determine the lowest temperature at which a hot surface will ignite combustible dust or powders when settled as a dust layer.

How does the Layer Ignition Temperature (LIT) test work?

Your test sample is placed onto an isothermally heated hotplate and formed into a 5 mm layer. Once an ignition temperature is observed, the hotplate temperature is reduced and retested. This is then repeated with fresh combustible dust until the lowest ignition temperature of dust layers are established.

What does Layer Ignition Temperature (LIT) data do?

The layer ignition temperature test is one of the three core tests for accessing a material’s ignition sensitivity when exposed to hot surfaces. The hot surface ignition temperature of dust layers are generally used when the avoidance of ignition sources’ is the ‘basis of safety’ for an operation.

This dust layer test data is required for defining the maximum operating temperature for electrical and non-electrical equipment used in areas where test materials are present, or dust accumulation may occur.

What is the benefit of the Layer Ignition Temperature (LIT) test?

The avoidance of sources of ignition as the ‘basis of safety’, is often used for processes such as powder handling systems; charging, storage vessels, from sacks, IBCs or FIBCs, pneumatic conveying, milling and tabletting operations.

Many materials that can create explosive atmospheres are found to be insensitive to ignition and therefore, it is easy, practical and cost-effective to ensure that an ignition source capable of initiating a dust explosion is not present.