Minimum Explosible Concentration (MEC) Testing

CONTACT US

CONTACT USOur UK laboratory generates flammable & explosive test data for your combustible dust and powders. The Minimum Explosible Concentration test is conducted to determine the minimum quantity of combustible dust dispersed in the air, as suspended dust clouds, that can form a flammable atmosphere.

The Sigma-HSE Advantage

Request a Free MEC Quote

Frequently asked questions

What are your Standards & Schedule of Accreditation

BS EN 14034 part 3 / ASTM E1515

What is the Minimum Explosible Concentration (MEC) test?

The Minimum Explosible Concentration (MEC) or Lower Explosive Limit (LEL) test is conducted to determine the minimum quantity of combustible dust dispersed in the air, as a cloud that will form a flammable atmosphere.

How does the Minimum Explosible Concentration (MEC) test work?

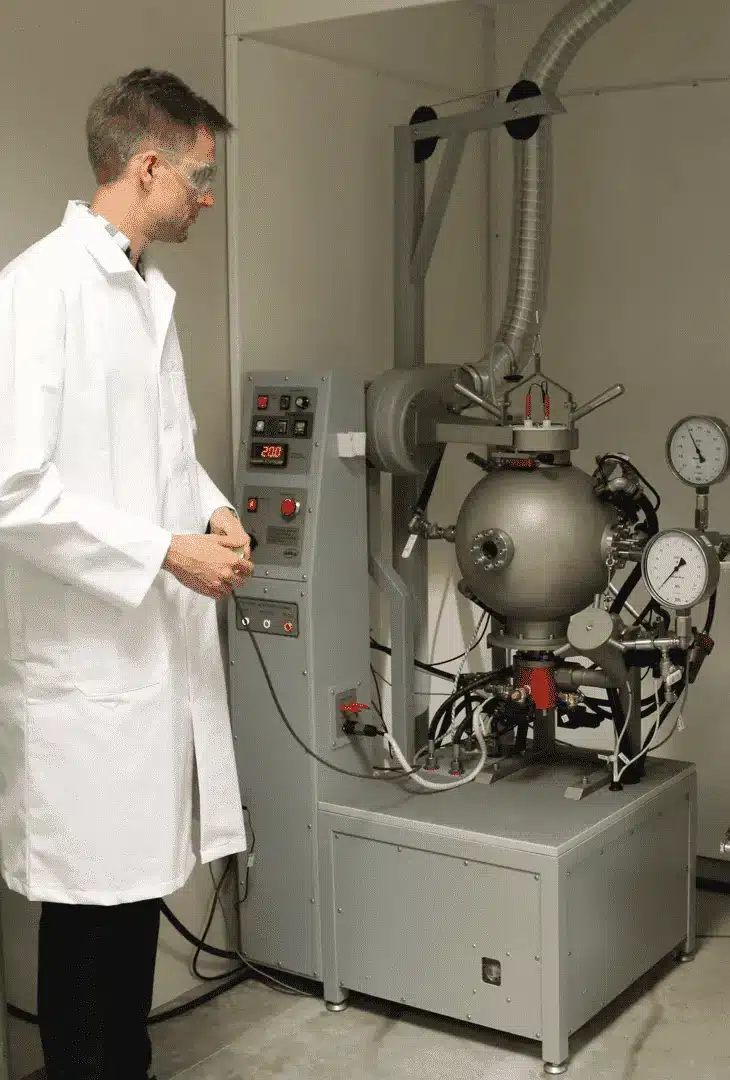

Working through a range of decreasing combustible dust concentration, a dust dispersed begins in an enclosed space (20L explosion vessel/sphere) using dry compressed air.

The suspended dust cloud is then exposed to a large 2 kJ chemical ignition source and the following dust explosion is monitored, measured, and recorded, using high-accuracy piezoelectric transducers.

Once ignition is achieved, a range of combustible dust/powder concentrations is then reduced until ignition is not possible and the minimum explosion concentration is established.

What does Minimum Explosible Concentration (MEC) data do?

Data generated by the Minimum Explosible Concentration (MEC) test is predominantly used to ensure that levels of airborne dust are kept below the minimum threshold by which a flammable atmosphere can be created and a combustible dust explosion could occur. It may also confirm if a material is appropriate for processes with an established LEV system or a set dust extraction rate.