No business wants to experience losses from fires and explosions.

We all know that such events can potentially cause harm to people, the environment, business and your brand reputation.

Many commercial and industrial manufacturing facilities handle flammable powders, liquids and gases.

Although many materials handled are not classified as dangerous, they can still burn or explode.

Examples may include, powders and dusts, such as flour or sugar which have resulted in some catastrophic fires and explosions such as Imperial Sugar (Georgia, USA) 2008.

By detailing relevant UK and EU legislation, suitable equipment grading and real-world operational examples, this article seeks to provide an understanding of the complexities that hazardous area classifications have on the procurement, inspection and maintenance of certified equipment.

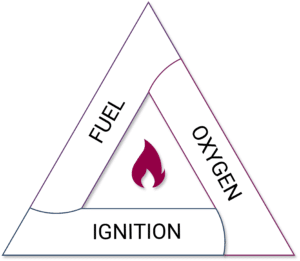

What is combustion?

Combustion is simply a chemical reaction of a substance with oxygen, e.g. natural gas reacting with air (oxygen) to generate carbon dioxide and water exothermically.

For something to burst into flame requires a source of fuel (essentially a substance that is capable of being oxidised), a source of oxygen or air and an ignition source.

This is often called the ‘fire triangle’.

Removal of any one of the components will prevent combustion.

Inside a natural gas pipeline, although the natural gas is classified as an extremely flammable gas, it will not ignite if an ignition source is present – there is no oxygen or air present.

But if a leak occurs into the open atmosphere, the gas will mix with the air and produce a flammable or explosive atmosphere.

It is pertinent to state that generally, liquids and solids do not burn – it is the vapours given off from the liquids and solids (when heated) which can ignite.

Liquids give off sufficient vapour to ignite if the temperature of the liquid is above the liquid’s flashpoint.

Toluene, for example, is a common solvent that has a flashpoint of 4°C, so under typical ambient conditions the liquid will generate a flammable or explosive atmosphere.

Legislation and hazardous zones

In the UK there is specific legislation for users of flammable or explosive materials.

These are the Dangerous Substances and Explosive Atmospheres Regulations (DSEAR) 2015 which require users to determine how and where flammable atmospheres can exist; categorisation of the extent or size of the flammable atmosphere and its likelihood of being present – this is known as the Hazardous Area Classification which results in zones of either 0, 1 or 2 (for vapours and gases) or 20, 21 or 22 (for combustible dusts); and then to ensure that only certified electrical and mechanical equipment (including lighting units) are present within these zones.

Outside of the extent of the zones, these can be designated as non-hazardous, and therefore no precautions such as certified or ‘protected’ equipment is necessary.

The extent of hazardous zones

The extent or size of the zones will be determined by the quantity of vapour produced which will be determined by temperature and pressure.

The extent can be calculated but there are many examples of typical zones for typical equipment items within the applicable standards.

The hazardous zones mentioned above are risk-based zones.

Risk is a function of the consequences of a hazard (a fire resulting from the ignition of a flammable or explosive atmosphere) and its likelihood (the probability of an effective ignition source being present within the flammable or explosive atmosphere).

The overall aim is to ensure that the risk is acceptable.

Sometimes a flammable or explosive atmosphere can be present continuously, for example, the vapour space of an atmospheric solvent tank where then liquid is present at a temperature above its flashpoint.

Sometimes the flammable or explosive atmosphere is only present during a particular operation, for example, during a solvent-based paint spraying operation or decanting of liquids into a reactor vessel.

Other times the flammable or explosive atmosphere may be only present during a malfunction, for example, a container of solvent is leaking or spills into a local area.

These three cases are described by the standards of the DSEAR Regulations based on their grade; which can be continuous, primary and secondary.

As a user it is your responsibility to determine where on your processes flammable or explosive atmospheres exist and the grade of release.

Once the grade of release is determined, this translates directly into the hazardous zones.

Continuous grades of release result in a Zone 0 (for vapours or gases) or a Zone 20 (for combustible dusts).

Primary grades of release result in a Zone 1 or a Zone 21.

Secondary grades of release result in a Zone 2 or a Zone 22.

What to do with your information?

So, with knowledge of the substance involved and the hazardous zone, this information can be forwarded to your supplier/manufacturer of certified equipment if this equipment is to be located within the hazardous zone.

Essentially the supplier/manufacturer will certify that the equipment has been designed and constructed to meet the essential safety requirements, typically following the guidelines of ISO 80079-36 as an example for mechanical equipment.

On delivery the equipment will be marked accordingly, but specifically with what is known as an Equipment Protection Level (EPL).

Manufacturers and equipment categories

Just to confuse matters, although you have provided the zonal information, the equipment manufacturers work to an equipment category – equipment for use in Zone 0 or 20 will have an EPL of Ga or Da; equipment for use in Zone 1 or 21 will have an EPL of Gb or Db; equipment for use in Zone 2 or 22 will have an EPL of Gc or Dc.

The appropriate legislation that suppliers and manufacturers must comply with for certified equipment is the Equipment for Use in Potentially Explosive Atmospheres Regulations, usually known as the EPS Regulations.

These Regulations define two groups of equipment:

- Group I – for underground mining applications and surface parts of mines.

- Group II – for surface industry and there are three categories

These are then given categories based on the hazardous zone in which they operate within:

- Category 1 (provides very high level of protection – very low probability of ignition) (Zone 0 and or 20)

- Category 2 (high level of protection) (Zone 1 and or 21)

- Category 3 (normal level of protection) (Zone 2 and or 22)

Real world operations – spray booth

All the above is perhaps clearer if a worked example is illustrated.

Let’s assume that you spray paint articles with solvent based (toluene) paint (flashpoint less than ambient temperatures) in a spray booth.

Let’s further assume that the spray booth is located within an internal room of your factory.

The spray booth will essentially consist of a metal booth with a filter cloth on the back face.

The rear face of the booth is extracted via ductwork to outside at high level via an internal electrically driven extraction fan.

An integral lighting unit is located on the ceiling of the spray booth and the internal room also has lighting units.

The switch for the room lighting is installed outside of the room, but the integral lighting unit installed in the roof of the spray booth is attached on the outside of the spray booth itself.

Real world operations – where to start?

The first task is to determine if flammable or explosive atmospheres can be present.

The paint used has a flashpoint which is lower than ambient temperatures (obtained from the paint material safety data sheet).

So, if the lid is removed from the paint can, a flammable or explosive atmosphere will result.

The spraying operation itself will by its action cause turbulent mixing with air which will produce a flammable or explosive atmosphere, so during the spraying operation within the spray booth, a flammable or explosive atmosphere will be present.

The filter will remove any liquid droplets, but vapour will be transferred into the extraction ductwork.

With the extraction operating normally, the airflow should reduce the concentration of the vapours within the ductwork to below an explosible concentration, but if the extraction malfunctions or does not have the specified performance, or not turned on, then a flammable atmosphere may be created within the ductwork.

Real world operations – spraying operations

During the spraying operation under normal operating conditions, the whole of the internal volume of the spray booth may contain a flammable or explosive atmosphere.

The question is ‘what is the grade of release?’

As discussed previously, this will be determined primarily by how often the spray booth is operated.

Spray painting is generally a batch operation, so it is likely that there is more time when spraying is not undertaken than when it is.

This means that the grade of release is a primary source.

This, therefore, results in the internal volume of the spray booth being a Zone 1.

This is also in line with the HSG 140 standard.

In normal operation the paint will be directed towards the article to be painted and away from the operative and towards the extraction.

However, it is possible that the spraying may on rare occasions be directed into the room, presumably accidentally; or if the spraying is undertaken with the extraction system off.

This will result in a Zone 2 within the room, or partially within the room.

With the extraction system off or malfunctioning, a flammable or explosive atmosphere may be created within the extraction ductwork, so a Zone 2 may exist.

Real world operations – lighting units

We all know that lighting units can get hot, or the components of the lighting units (including the switch) may spark, so if these are present within a flammable or explosive atmosphere a fire may result.

In our example, there is a lighting unit present in the roof of the spray booth and the switch is located just on the outside of the spray booth.

Therefore, both the lighting unit and the switch will need to be certified equipment for use in a Zone 1 environment.

Similarly, the room lighting unit and the extraction fan will need to be certified for use in a Zone 2 environment.

The electrical motor for the extraction fan is located outside the ductwork, so it is present in a non-hazardous location and does not need to be certified equipment.

Real world operations – atmosphere groups

There are a couple of additional things that need to be considered to provide the necessary level of protection from certified equipment.

One is associated with the sensitivity of substances to ignition, which is known as the Atmosphere Group.

There are three types for gases and vapours for non-mining applications – IIA, IIB, and IIC.

Group IIA relates to substances such as methane and propane (and many other typical solvents, for example, toluene); Group IIB for ethylene (more sensitive to ignition); and Group IIC for hydrogen and acetylene (particularly easily ignitable substances).

The second is the Temperature Classification.

Temperature classifications range from T1 to T6. T6 equipment items are manufactured to avoid surface temperatures exceeding 85°C, whereas T1 equipment items can generate surface temperatures up to 450°C.

For vapours and gases, it is the auto-ignition temperature that determines the temperature classification.

The autoignition temperature of toluene is 480°C which essentially means that at this temperature or above, toluene will ignite.

Therefore any equipment item should not generate this level of temperature if we require to prevent ignition. Tables exist within the standards which determine the temperature classification. In this case, the temperature classification is T1.

For the lighting unit and switch installed within our spray booth illustrative example you have been able to define the applicable zone and provide the necessary information on the flammable substance being used in your process.

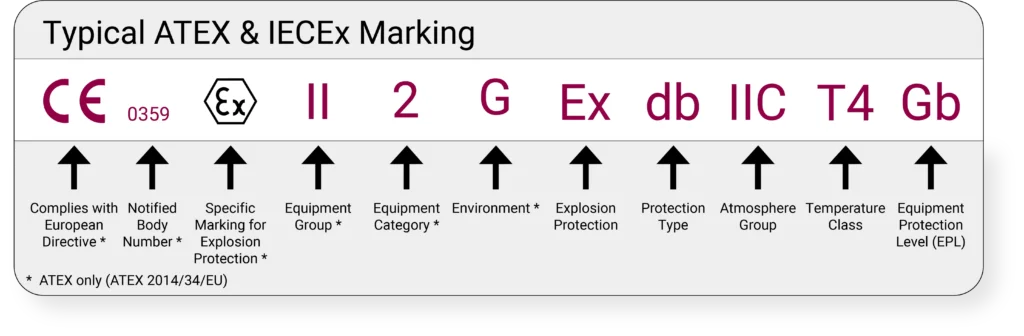

The manufacturers of the lighting system will use this information to manufacture the lighting unit for this zone and substance, and the certification and name plate attached to the lighting unit and switch which provide information as shown below.

You need to double check that the certification information is correct. A typical ATEX marking can be like the following:

‘Ex II 2 G Ex db IIA T1 Gb’ where:

- II refers to the Equipment Group (use in surface industries)

- 2 refers to the Equipment Category (high level of protection)

- G refers to the environment (vapours or gases)

- Ex and db refer to the Explosion Protection Concept and protection type (in this case the lighting unit and switch will be flameproof. There are other protection types such an intrinsically safe, pressurisation etc.)

- IIA refers to the Atmosphere Group (based on the substance in use)

- T1 refers to the temperature classification (based on the autoignition temperature of the substance)

- Gb refers to the Equipment Protection Level

For the lighting units present within the internal room within a Zone 2 environment, or the extraction fan contained within the ductwork the information would be:

Ex II 3 G Ex db IIA T1 Gc

CompEx competence

Protecting your personnel and business from fires and explosion is crucial, and there should be no surprise that specific precautions need to be built into your processing operations and installations.

But just carrying out hazardous area classification and installing certified equipment is not all that you have do.

For this equipment to be effective at preventing fires and explosions you need to inspect it and maintain it.

For the certified equipment, this is not a job for a normal electrician.

The legislation requires that specifically competent individuals are used to inspect and maintain certified equipment.

The CompEx Scheme

One such scheme to assure this competence is the CompEx scheme, where electricians are required to prove their competency in several areas before being accredited as competent.

Electricians at the facility or externally contracted ones should be CompEx trained appropriately to Ex 1-4 (Gas and Vapours).

They should also follow the two main standards:

- To install electrical equipment to ensure it meets the requirements of EN 60079-14.

- To inspect and maintain the electrical equipment in accordance with the requirements of EN 60079-17.

Conclusion

Organisations must understand their processes in order to designate potentially hazardous areas and understand the risk from hazardous materials.

This entire operation requires input from a competent person.

The first task is to determine if a flammable or explosive atmosphere can be present in your process.

If new equipment is to be used within a hazardous zone, the equipment supplier or manufacturer must be informed of the nature of the hazardous material and provided with the necessary safety data to ensure that any equipment built can be used in accordance with fundamental safety requirements.

Following procurement, a competent person must double check that the certification information is correct, while being responsible for inspection and maintenance procedures.

The procurement, inspection and maintenance of certified equipment for these zones require a holistic approach from a competent person to ensure that they provide effective safety measures.