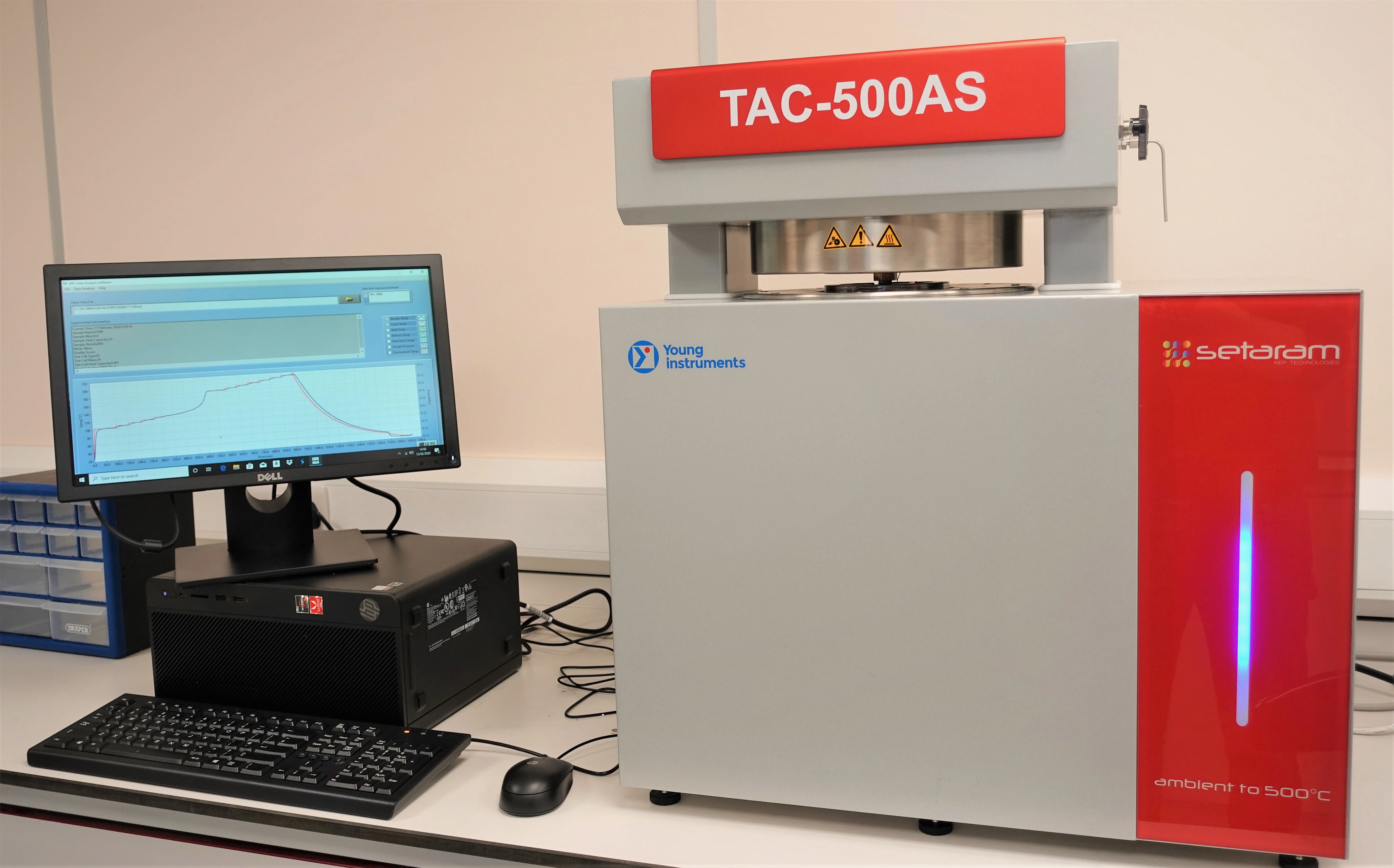

Accelerating Rate Calorimeter (ARC) Testing

Our UK laboratory generates thermal screening and reaction calorimetry test data for your hazardous materials and/or reactions. The Accelerating Rate Calorimeter (ARC) is used to assess the time, temperature and pressure data of a material as it undergoes a physicochemical change under near adiabatic conditions.

Data from the ARC allows for an accurate prediction of thermal and pressure events in the processing, storage, and shipping of potentially hazardous chemicals.

The Sigma-HSE Advantage

Request a Free ARC Testing Quote

Frequently asked questions

What is your standard methodology?

ASTM E 1981-98

What is the Accelerating Rate Calorimeter test?

The Accelerating Rate Calorimetry test is conducted to assess the time, temperature and pressure data of a material as it undergoes a physicochemical change under near adiabatic conditions.

How does the Accelerating Rate Calorimeter work?

A 3-5 g sample is placed in a closed low heat-capacity vessel and positioned within the calorimeter. The design of the system to be adiabatic allows for highly accurate exothermic decomposition onsets to be determined with confidence. The system is typically operated in a Heat-Wait-Search mode, which increases the system temperature in steps of typically 5-10 °C, with a temperature range of up to 450 °C to be tested.

At each temperature step the system will dwell at the temperature, and monitor the sample for any temperature increases with a sensitivity of down to 0.02 °C/min. As soon as the sample is detected to be increasing in temperature, then the furnace will match the temperature of the sample, mimicking the scenario of zero heat loss to the environment. Exotherms will be tracked in this way until the decomposition is exhausted, or the maximum safety temperature is reached.

What data can I get from the Accelerating Rate Calorimeter test?

Time, temperature, and pressure range data are recorded continuously through the test, and this data can then be used to plot rates of changes in pressure and temperature. This data can also be used to calculate a time-to-maximum rate, obtain kinetic parameters, and calculate an adiabatic temperature rise/heat of reaction and SADT values.

What are benefits of the Accelerating Rate Calorimeter test?

Operation and analysis of the ARC with carefully designed testing packages will help to provide highly accurate decomposition onsets, power, TMR and other data, so that your material can be processed, transported and stored correctly and safely.

The ARC can also be used to investigate and determine the effects of catalysts, inhibitors, initiators, reactive atmospheres and materials of construction in desired chemical reactions.