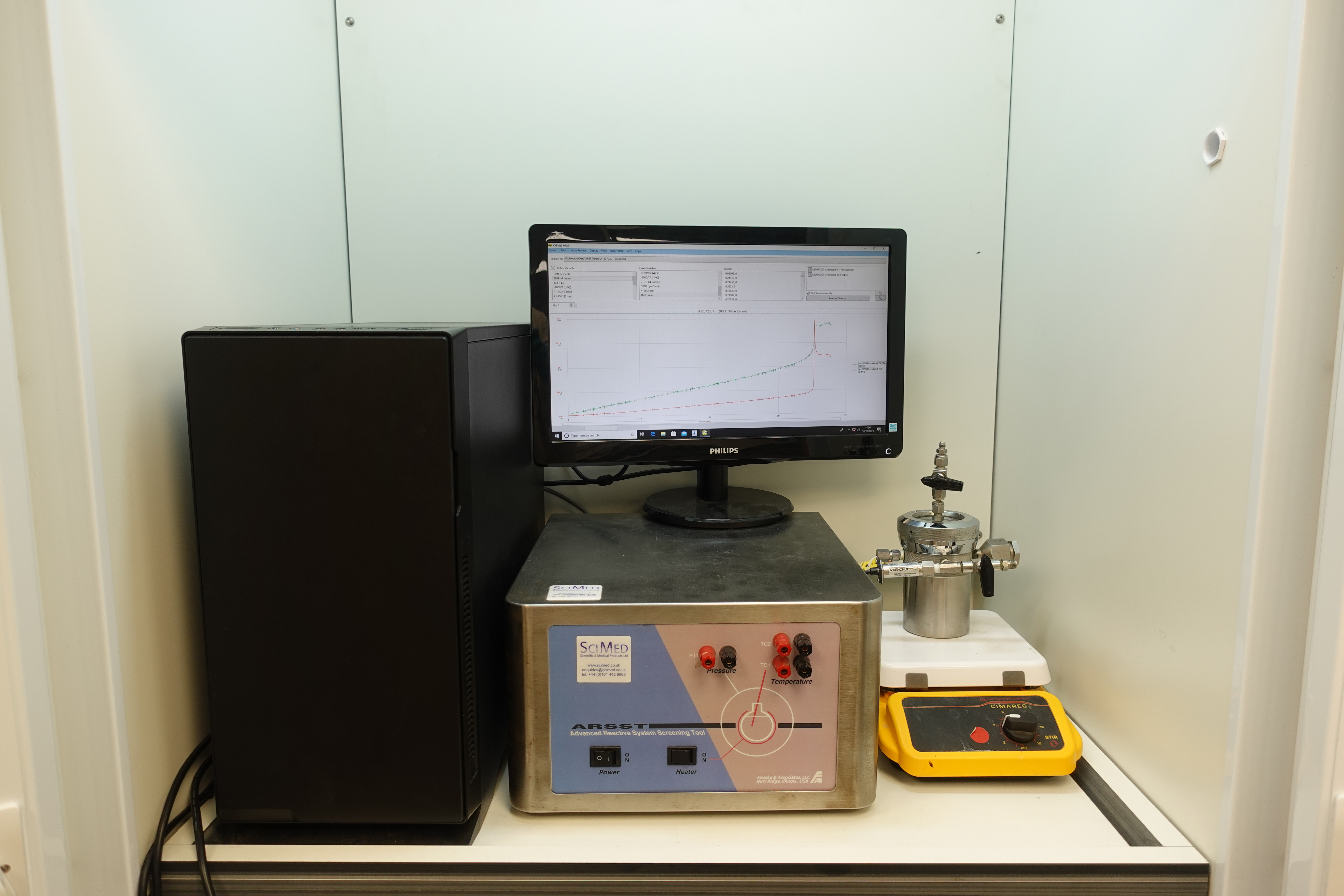

Advanced Reactive System Screening Tool (ARSST) Testing

Our UK laboratory generates thermal screening and reaction calorimetry test data for your hazardous materials or reactions. The Advanced Reactive System Screening Tool (ARSST) test is used to quickly detect and identify potential reactive chemical hazards in processes.

The ARSST will aid in characterising and accurately determining the thermal decomposition onsets of materials, and inherent adiabatic temperature rises to desired reactions, by utilising its unique low phi-factor testing cell. This screening method will help inform decisions regarding your process scale up, by anticipating full scale process conditions and required thermal energy management.

The Sigma-HSE Advantage

Request a Free ARSST Quote

Frequently asked questions

What is your standard methodology?

Industry standard tool for screening reactive systems, developed to compliment DIERS methodology for vent sizing.

What is the Advanced Reactive System Screening Tool (ARSST) test?

The Advanced Reactive System Screening Tool (ARSST) is an example of a pseudo-adiabatic calorimeter batch reactor tool that is used to quickly identify potential reactive chemical hazards in processes.

It consists of a well-instrumented pressure vessel that usually holds a spherical glass test cell that can heat a 10 ml sample at a specified ramp or rate, determining onset temperatures up to 400 °C. The reaction mixture, magnetic stirrer and thermocouple are introduced to this cell, while the pressure inside the vessel is measured by a pressure transducer. Due to the unique heating method by a wraparound heater, the sample is kept in a pseudo-adiabatic mode and no heat loss to the surroundings occurs.

What data can I get from Advanced Reactive System Screening Tool (ARSST) test?

Typical data outputs can include the following:

-

Rate of pressure rise

-

Heat of reaction

-

Heat of mixing

-

Total adiabatic temperature rise

-

Onset temperature

-

Tempering temperature

-

Self-accelerating decomposition temperature

-

Time to maximum rate (induction time profile)

What are the Advanced Reactive System Screening Tool (ARSST) benefits?

Flexible screening tool for analysis of varied Reactive Systems: basic reaction calorimetry possible with reagent mixing, thermal stability screening of mixtures and materials, and evolved pressure data to boot. Uses typically small sample sizes to compliment early-stage development.

Pseudo-adiabatic methodology for accurate determination of thermal decomposition onsets of materials, with the added benefit of pressure data collection.