Minimum Ignition Energy (MIE) Testing

CONTACT US

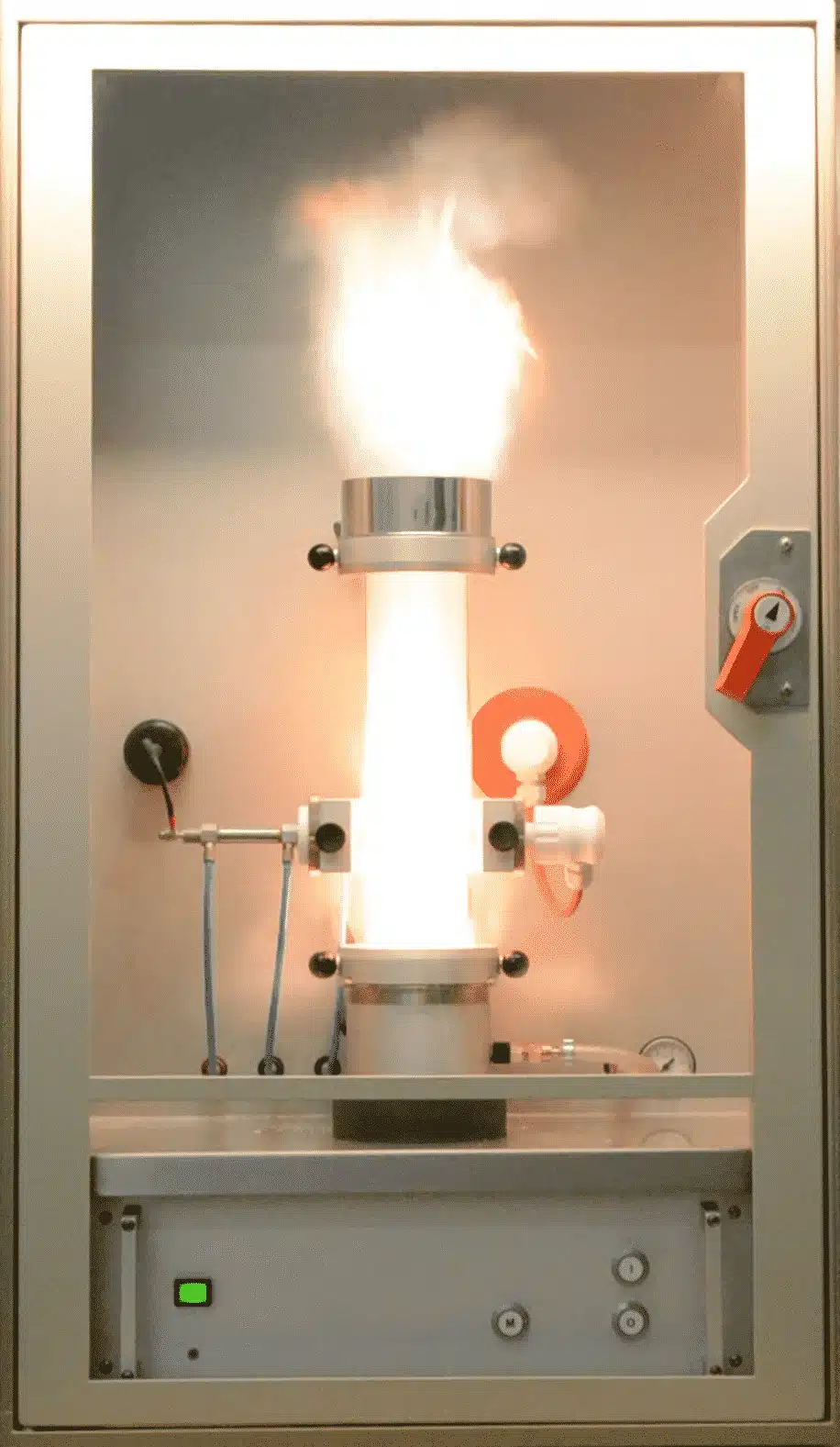

CONTACT USOur UK laboratory generates flammable & explosive MIE test data for your combustible dust and powders. This test determines the minimum ignition energy of a dust cloud in the air by using electrical spark ignition.

The Minimum Ignition Energy test will aid in characterising, preventing, protecting and mitigating combustible dust explosions and fire hazards.

The Sigma-HSE Advantage

Request a Free MIE Quote

Frequently asked questions

What are your Standards & Schedule of Accreditation

BS EN ISO IEC 80079-20-2 / ASTM E2019 / BS EN 13821 (withdrawn)

What is the Minimum Ignition Energy (MIE) test?

The Minimum Ignition Energy (MIE) test is conducted to determine the lowest spark energy that can ignite a powder when dispersed in the air as a dust cloud. A purely capacitive generated spark is used to assess the energy range of electrical and electrostatic discharges (brush, spark, transitional/propagating brush discharges).

An inductively generated spark is selected for mechanical (friction, impact and grinding, mechanical sparks) or electrical spark incendivity analysis.

How does the Minimum Ignition Energy (MIE) test work?

Working through a range of dust powder concentrations, potentially combustible dust is dispersed into compressed air past a 1.2L litre glass vessel using dry compressed air.

These momentarily suspended, dust cloud particles/clouds are then exposed to sparks of known energy for a selected duration. Energy is then lowered, while dust powder concentration and time delay are varied until the minimum ignition energy is established.

What does Minimum Ignition Energy (MIE) data do?

Minimum ignition energy data is typically used to define the minimum spark energy needed to ignite a cloud of combustible dust or process material in the working environment. MIE is one of three core tests where ‘Avoidance of Ignition Sources’ is the ‘Basis of Safety’ for an operation.

This approach tests combustible dust samples or powders to determine how sensitive they are to ignition sources such as electrostatic discharge, mechanical & electrical sparks and even a hot work surface area.

What are the Minimum Ignition Energy (MIE) benefits?

The basis and test method of safety is often used when charging vessels from sacks, IBCs or FIBCs, pneumatic conveying, milling and tabletting operations.

Combustible dust that can create a flammable atmosphere is found to be insensitive to ignition. Therefore, it is easy, practical and cost-effective to have test apparatus ensure that an ignition source capable of initiating a dust explosion is not present.

A sub-group of ‘Avoidance of Ignition Sources’ are the electrostatic properties of products and materials used in process environments.

This includes the electrostatic properties of materials being processed, electrostatic properties of containers and/or Personal Protection Equipment (PPE). This is particularly important in process conditions where the process equipment or materials are found to be very sensitive to an ignition source.